How The Steel Industry Is Raising The Bar

In Quality And Safety

Steel manufacturing has entered a new era-one defined by scale and volume, reliability, safety, and innovation. As infrastructure projects expand across India and globally, expectations from steel are higher than ever. Customers no longer seek strength; they seek long-term performance, safety, and quality. India's domestic steel demand is projected to grow by 8-9% in 2025, outpacing other major economies, driven by the steel-intensive sectors of housing and infrastructure construction. As part of this evolving environment, the industry is actively raising the bar and rightly so.

Quality Begins At The Source

Modern steel manufacturing is moving beyond traditional practices. Automated quality checks, digital monitoring, and tighter process controls are now standard in most advanced plants. Parameters such as chemical composition, strength, and ductility are monitored at every stage, from molten metal to finished product.

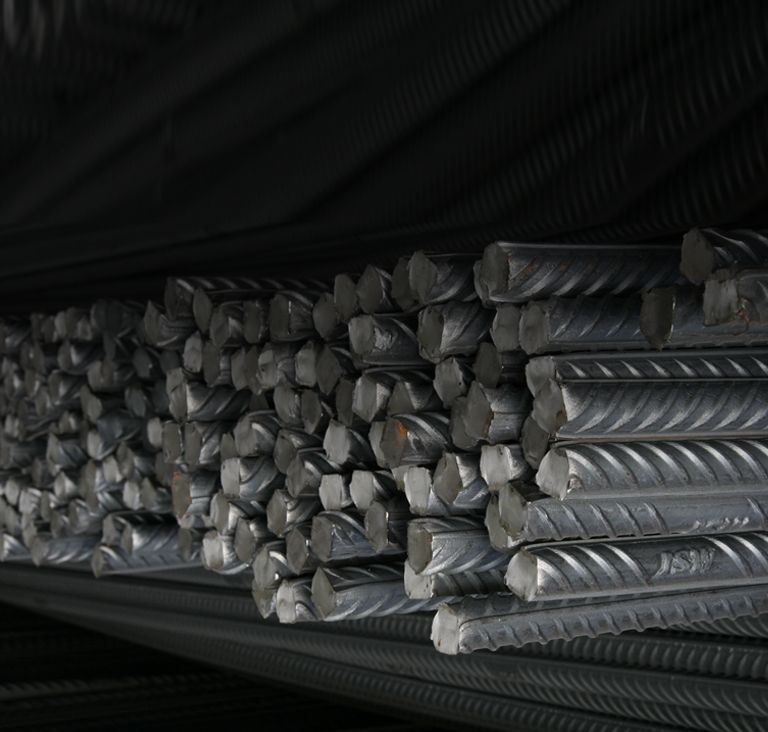

At JSW Steel, we have invested heavily in real-time analytics and process automation to enhance precision in every batch. For instance, our JSW TMT bars are produced using a state-of-the-art quenching and self-tempering process. This ensures superior mechanical strength and uniform quality, which is critical for earthquake-resistant and high-rise buildings. It's no surprise that the best TMT bars today are judged not just by their physical characteristics but also by how consistently they meet those standards.

Building Safety Into Every Layer

Safety in steel starts long before the product is delivered to the site. Today's standards go beyond tensile strength and yield value. There's a growing emphasis on consistent elongation, weldability, and resistance to fatigue.

We're seeing a greater adoption of non-destructive testing (NDT) techniques to evaluate internal flaws without compromising the product's integrity. The focus on workplace safety is equally strong, with automated material handling systems, PPE compliance, and training programs being key components of our culture.

As a leading player in the industry, JSW Steel Company follows a comprehensive approach that combines product safety and employee well-being. These two are not separate goals but a part of the same commitment to quality and responsibility.

Galvalume Coated Steel Is Gaining Ground

The construction industry is also shifting towards smarter, more sustainable materials. Galvalume-coated steel, for example, is increasingly used in roofing, cladding, and structural applications due to its high corrosion resistance and longer lifespan.

The preference is growing, especially in coastal and high-humidity regions, where material degradation is a serious concern. Using Galvalume products helps reduce maintenance costs and enhances structural safety over time, making it a wise choice for architects and engineers.

The Bar Is Higher—And That's A Good Thing

What we're seeing isn't a one-off shift but a steady evolution. From the design of steel to its delivery, quality and safety have become the driving forces behind every decision. Be it a JSW TMT bar or a roll of coated steel, the industry benchmark is rising, and we're proud to be part of that progress.