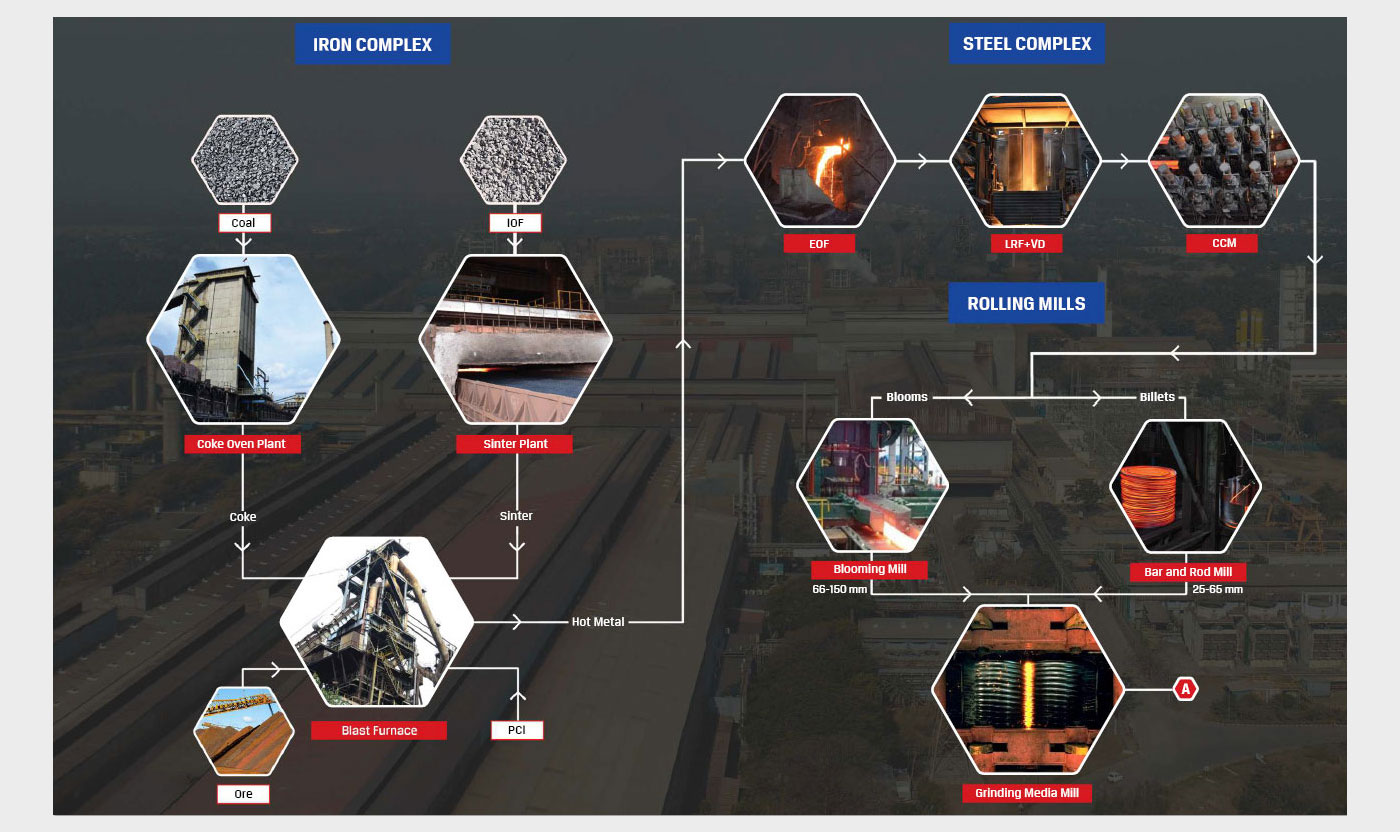

JSW Steel Salem Works is India's largest integrated special steel plant (long products) located in Salem, Tamil Nadu, India with an installed capacity of 1.15 million tons per year.

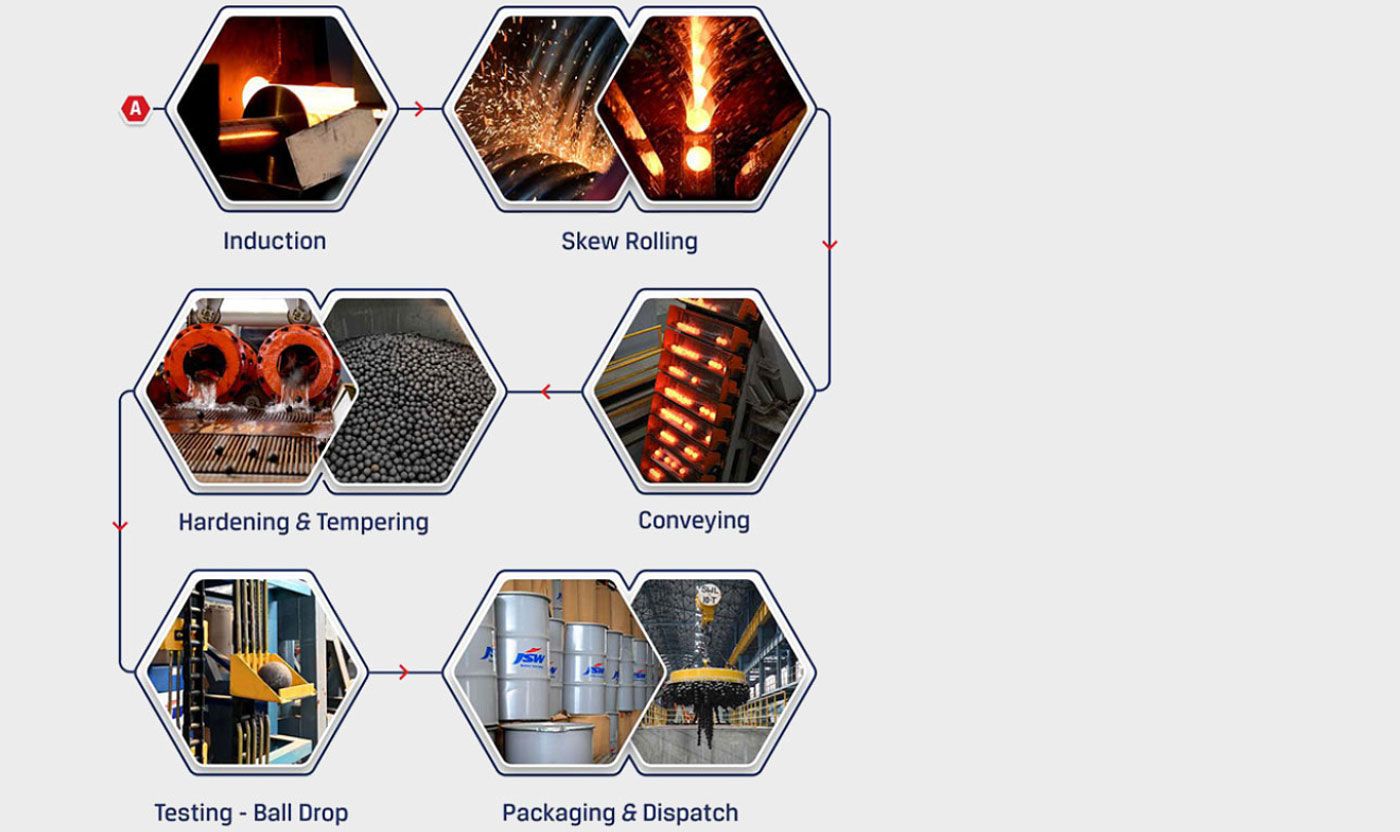

Product mix comprises Cast Blooms/Billets, Hot Rolled Round Bars, RCS Bars, Flat Bars, Wire Rod and newly added Grinding Media, which is one of the main consumables for the miningIndustry. Grinding Media is added to the product mix with the installation of its Mill with a capacity of one hundred thousand (100,000) tons per year at Salem Works

This Integrated Plant offers a unique edge in quality control for forged grinding media.

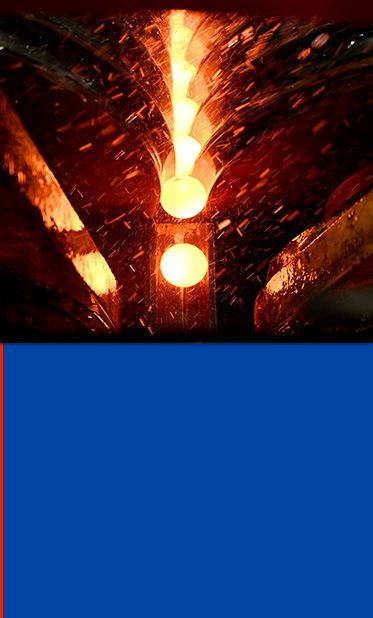

Production Process Path

The Grinding Media Mill (GMM) is the first of its kind in India, with a production capacity of one hundred thousand (100,000) tons per year. GMM will cater with the required quality for mining industries.

Grinding Media:

Appropriate for Secondary & Regrind Ball Milling:

Heat treated for Maximum Hardness & High Abrasive Resistance

| Ball Size (mm) |

Equivalent Ball Size (inch) |

Size Tolerance (%) |

Surface Hardness (HRc) |

Volumetric Hardness (HRc) |

Ball Weight (kg) |

C% | Si % | Mn % | P % | S % | Cr % | |

|

25 | 1" | ± 4% | 60 - 65 | 60 - 65 | 0.06 | 0.62 - 0.67 | 0.15 - 0.30 | 0.70 - 0.85 | 0.025 max | 0.010 max | 0.30 - 0.40 |

|

40 | 1.5" | ± 4% | 60 - 65 | 60 - 65 | 0.26 | 0.62 - 0.67 | 0.15 - 0.30 | 0.70 - 0.85 | 0.025 max | 0.010 max | 0.30 - 0.40 |

|

50 | 2" | ± 4% | 60 - 65 | 60 - 65 | 0.51 | 0.62 - 0.67 | 0.15 - 0.30 | 0.70 - 0.85 | 0.025 max | 0.010 max | 0.30 - 0.40 |

|

60 | 2.3" | ± 4% | 60 - 65 | 60 - 65 | 0.89 | 0.62 - 0.68 | 0.20 - 0.40 | 0.85 - 1.00 | 0.025 max | 0.010 max | 0.60 - 0.70 |

|

70 | 2.8" | ± 4% | 60 - 65 | 60 - 65 | 1.41 | 0.62 - 0.68 | 0.20 - 0.40 | 0.85 - 1.00 | 0.025 max | 0.010 max | 0.60 - 0.70 |

|

80 | 3" | ± 4% | 60 - 65 | 60 - 65 | 2.1 | 0.62 - 0.68 | 0.20 - 0.40 | 0.85 - 1.00 | 0.025 max | 0.010 max | 0.60 - 0.70 |

|

90 | 3.5" | ± 3% | 60 - 65 | 60 - 65 | 3 | 0.62 - 0.68 | 0.20 - 0.40 | 0.85 - 1.00 | 0.025 max | 0.010 max | 0.60 - 0.70 |

Appropriate for SAG Milling or Primary Milling:

Heat treated to achieve Optimised Hardness & High Impact Resistance

| Ball Size (mm) |

Equivalent Ball Size (inch) |

Size Tolerance (%) |

Surface Hardness (HRc) |

Volumetric Hardness (HRc) |

Ball Weight (kg) |

C% | Si % | Mn % | P % | S % | Cr % | Mo% | |

|

100 | 4" | ± 3% | 55-60 | 55-60 | 4.11 | 0.57 - 0.62 | 0.35 - 0.45 | 0.95 - 1.12 | 0.025 max | 0.010 max | 0.75 - 0.80 | 0.055 - 0.065 |

|

115 | 4.5" | ± 3% | 48-55 | 48-55 | 6.26 | 0.57 - 0.62 | 0.35 - 0.45 | 0.95 - 1.12 | 0.025 max | 0.010 max | 0.75 - 0.80 | 0.055 - 0.065 |

|

125 | 5" | ± 2.5% | 48-55 | 48-55 | 8.03 | 0.57 - 0.62 | 0.35 - 0.45 | 0.95 - 1.12 | 0.025 max | 0.010 max | 0.75 - 0.80 | 0.055 - 0.065 |

|

140 | 5.5" | ± 2.5% | 48-55 | 48-55 | 11.3 | 0.57 - 0.62 | 0.35 - 0.45 | 0.95 - 1.12 | 0.025 max | 0.010 max | 0.75 - 0.80 | 0.055 - 0.065 |

|

150 | 6" | ± 2% | 48-55 | 48-55 | 13.87 | 0.57 - 0.62 | 0.35 - 0.45 | 0.95 - 1.12 | 0.025 max | 0.010 max | 0.75 - 0.80 | 0.055 - 0.065 |

Stringent Quality Control & State of the art Testing Facility:

JSW Steel Grinding media under goes a stringent Quality Control Process to ensure defect-free product

- Ball Drop Test (Upto 10 m Height)

- Electron Microscope

- Microscopic Structure: Tempered Martensite

- Surface and Volumetric Hardness Test

- Immersion Ultrasonic Testing

- Automatic UST

State of the art Testing Facility:

Packaging

JSW Grinding Medias are available in 1 or 2-ton High-Density Polyethylene bags, each equipped with secure lifting straps. These bags are expertly strapped onto 1m x 1m wooden pallets for easy transportation. "

class="img-responsive">

JSW Grinding Medias are available in 1 or 2-ton High-Density Polyethylene bags, each equipped with secure lifting straps. These bags are expertly strapped onto 1m x 1m wooden pallets for easy transportation. "

class="img-responsive">

We also offer the option of loose ball supply in half-height containers, standard 20ft. containers, or via open-top trucks. "

class="img-responsive">

We also offer the option of loose ball supply in half-height containers, standard 20ft. containers, or via open-top trucks. "

class="img-responsive">

JSW Grinding Medias are packed in 200 lit metal drums, arranged on pallets. Each drum contains approximately 1 ton of gross weight balls. Drums can be directly loaded onto truck trailers or securely strapped onto wooden pallets as per requirement."

class="img-responsive">

JSW Grinding Medias are packed in 200 lit metal drums, arranged on pallets. Each drum contains approximately 1 ton of gross weight balls. Drums can be directly loaded onto truck trailers or securely strapped onto wooden pallets as per requirement."

class="img-responsive">