Steel’s Pertinence in Energy Development

The world is developing at an exponential rate as is the need for energy, which is the driving force of development. The Global World Energy Outlook of International Energy Agency (IEA) forecasts a 27% rise in global demand for energy by 2040, with most of the demand coming from developing countries.

In view of the looming danger of climate change and global warming, the biggest challenge is to meet the ever-growing need for energy while ensuring sustainability. It would require a high degree of innovation in the way most industries function. Most importantly, it would necessitate the availability of more renewable energy.

With this perspective, steel is and will continue to be critical for supplying the world with the required renewable energy apart from conventional sources of energy. Whatever the source, be it based on nuclear technology, wind, solar, geothermal or even fossil fuels, steel has a crucial role to play in producing and distributing energy as well as improving energy efficiency.

Steel finds application in various arenas of renewable energy. Here’s how.

Solar Energy: Steel is used as a base for solar thermal-panels and in both the inner and outer shells of water tanks, pumps, and heat exchangers for converting solar energy into electricity or hot water. To ensure maximum absorption of sunlight, coatings are also applied on the steel. JSW Galvos’ premium coils and sheets also boast of superior features and are especially designed for the solar sector.

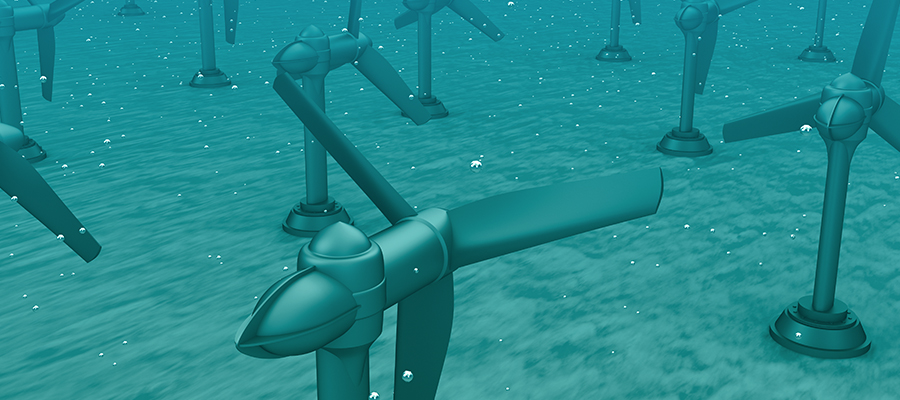

Wave and Tidal Energy: Steel is formulated to withstand the challenges of the marine environment. Which is why it is used to manufacture devices for generating wave energy. In addition, steel pile is the main component of a tidal turbine in tidal energy systems.

Hydroelectricity: High-strength steel is widely used to reinforce concrete dams for production of hydroelectricity as it offers maintenance-free and long-lasting solutions. Using steel protects the system from seawater corrosion, abrasion, and biofouling.

Offshore Wind Energy: The corrosive nature of seawater in which offshore windmills are located demands the use of a corrosion resistant material. Therefore, steel is the main material used in onshore and offshore wind turbines. Almost every component of a wind turbine including the foundation, gears, casings, fasteners, and safety cables are made of steel. Stainless steel ensures a lifetime of fifty years or more for turbines and minimises the maintenance.

Geothermal Energy: Because the water produced in geothermal sources is extremely hot, it is important to use a material that can ensure a safe and continuous operation of components such as heat exchangers, condensers, piping, filters, pumps, and valves. Being highly resistant to corrosion, stainless steel is the best choice for the equipment material.

Steel is used in nuclear and fossil fuel-based energy as well to make equipment for mining ores, extraction and production of oil and natural gas, and pipelines for their distribution. Furthermore, it is used to construct storage tanks and power plants. Also, the waste heat generated from power plants that is used for power generation (through heat energy) is transported exclusively via steel pipes because they are resistant to corrosion.

Steel is crucial when it comes to distribution of the produced energy and electricity. The magnetic core of transformers that step down the power station voltage to household voltage is made of steel. Continuous development of new electrical steel grades has reduced about 35% in energy loss in modern transformers as compared to conventional ones. Besides cables, generators, and transformers, steel is also favoured in building transport networks like bridges, tunnels, and rail tracks.

Hence, steel is crucial in assuaging the global demand for energy as it enables a smooth transition from non-renewable to renewable sources of energy. More and more renewable energy enterprises are becoming a part of this transition and steel is completely reshaping the energy sector.

Information sources: World Steel Association, Volta Green