Facts You Must Know

What is metal rolling?

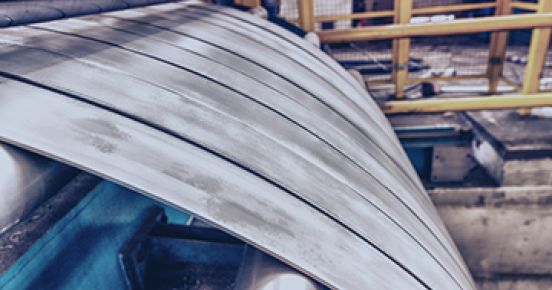

In metalworking, passing metal stock through one or more pairs of rolls to manipulate the thickness is known as rolling. In other words, when molten steel is rolled between rollers to reduce its thickness and make it uniform, the steel is said to have been rolled.

Metal rolling has been a part of human history for a very long time, with evidence of basic rolling mills, known as slitting mills, found in the Middle East and South Asia as early as 600 BC. Much later in 1783s, Henry Cort of England secured a patent for his application of grooved rolls for rolling iron bars. The modern rolling practices have been derived from this principle.

What are the types of rolling?

There are two main types of rolling, namely hot rolling and cold rolling. In hot rolling, metals are milled at a temperature that prevents recrystallisation of the metal, usually above 1000 degrees Fahrenheit. Hot-rolled metals typically have little directionality in their mechanical properties and deformation-induced stresses. Sheet metals that have simple cross-sections are produced using hot rolling. Such products are used to make rail tracks, truck frames, water heater, agricultural equipment, metal buildings and so on.

In the cold rolling process, metals are milled below their recrystallization temperatures. The metal is usually worked at room temperature, and this increases its strength through strain hardening, by up to 20%. Cold rolled metals also have a better surface finish and tighter tolerances than hot rolled ones.

JSW Steel produces both hot and cold rolled steels at its manufacturing units in Dolvi, Maharashtra, and Vijayanagar, Karnataka. The two units have a combined capacity of 17 MTPA. The Vijayanagar unit houses the widest cold rolling mill for automotive steel in India. The Dolvi unit produces high-quality hot rolled steel coils using a combination of the advanced Conarc process and thin slab casting technology. Additionally, all products conform to JIS, EN, ASTM and IS standards.

What are the different rolling processes?

Metalworking uses a number of different rolling processes to manufacture a variety of products. Ring rolling, roll bending, roll forming, profile rolling, and controlled rolling are some of the most popular rolling processes, each having its unique applications and advantages.

While there are various types of rolling mills - two-high rolling mills, three-high rolling mills, four-high rolling mills, tandem rolling mills and cluster rolling mills – the primary construction principle of mills is common to all and independent of the type of rolling being performed.