About Cold Rolled Steel

What is cold rolled steel?

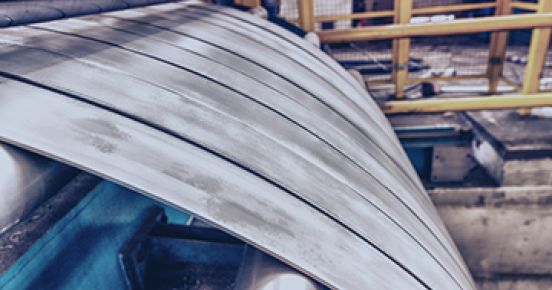

Cold rolled steel is manufactured using a milling process that involves heating the metal and leaving it to cool to the room temperature. At this point, the steel has not been fully finished and is known as half-product. After it reaches the room temperature, the half-products are sent to cold reduction mills where they are formed by either press-braking or cold roll forming to achieve the desired shape. During rolling, a film of oil is applied to the metal surface to counter material wear, which gives the finished cold rolled steel its characteristic smooth, shiny surface.

What are the important properties of cold rolled steel?

Ductility is the most important and sought-after property of cold rolled steel. It offers easy and precise formability, without losing its strength and toughness. Cold Rolled Steel is known for its ability to hold tight tolerances and retain few surface imperfections. Additionally, it is non-shrinking and non-creeping at ambient temperatures.

What are some key applications of cold rolled steel?

High-precision projects and products are the largest consumers of cold rolled steel. Its easy formability makes it essential for moderate draw applications. Which is why it is perfect for use in many home appliances and metal furniture, such as filing cabinets and lockers. Cold rolled steel is also widely used in construction where it is used to build steel sheds, industrial buildings, garages and the like.

Cold Rolled steel augmenting the solar panel industry

Apart from its usual applications, cold rolled steel is the preferred construction material for making solar panels. With the growing consciousness towards green energy, solar panel makers are constantly looking for cost-effective and reliable materials that can ensure superior end product quality. With its unyielding strength, precise ductility and light weight, cold rolled steel meets all the requirements. Additionally, cold rolled steel solar panels can be prefabricated and simply installed at the site, significantly cutting down project completion time.

JSW Steel’s Cold Rolled Products

At JSW Steel, cold rolled closed annealed coils and sheets are manufactured at the Vijayanagar plant’s continuous annealing line, which is also the widest cold rolling mill for automotive steel in India. JSW Steel’s cold rolled closed annealed coils are manufactured in Deep Drawing, Extra Deep Drawing, Interstitial Free Steels and High Strength grades, which are conformed to JIS, EN, ASTM and IS standards. Dimensional accuracy is guaranteed by an automatic thickness control system using advanced numerical models.