Transparency to Customers

JSW Group is committed to operating processes and conducting marketing promotions in a transparent, responsible manner that shares product information to customers with absolute transparency – both as per regulatory requirements specific to certain geographies and as per voluntary schemes.

Life-cycle Assessment

We cognize that product design and consumer behaviour can affect the overall environmental performance and efficiency of a product. Among the tools and methodologies available to evaluate the environmental, economic and social performance of materials and consumer products (including their impact on climate change and natural resources), life cycle assessment (LCA) provides a holistic approach that considers the potential impacts from all stages of manufacture, product use and end-of-life (reuse, recycling or disposal).

It is essential to recognize that a full life cycle approach is the best way to assess a product's impact on the environment. It is also, therefore, the best way to help society make informed decisions on the use of materials and their economic importance. We at JSW Group have recognised the need to develop a sound methodology to assess the life cycle inventory of our key products and services, to support the markets and customers. LCA study has been completed for seven of our products, using the GaBits software system for life cycle engineering, developed by Thinkstep AG.

Environmental Product Declaration

JSW Group attains product-specific Environmental Product Declarations (EPDs) that are made according to a transparent standard and verified by the external agency according to international standards. Our presence lies in the heavy manufacturing sectors of steel and cement, both of which are extensively used in the construction industry. By using the EPD awarded products of JSW, our customers in the construction industry can earn points for certification schemes like LEED and BREEAM. The level of transparency and reporting through EPD allows us to identify environmental hotspots in the life cycle of a product, optimum resource decisions to be made, and demonstrates the sustainability of our products that go into construction projects.

What is Environmental Product Declaration?

An Environmental Product Declaration (EPD) is a voluntary declaration of the life-cycle environmental impacts of a product, an independently verified and registered document that communicates transparent and comparable information about the life-cycle environmental impact of products. The objective is to enable and support organisations in any country to communicate quantified environmental information to customers on the life cycle of their products in a credible, comparable, and understandable way, thereby assisting in product comparison.

EPD is based on a Life Cycle Assessment (LCA) study - a methodology to assess the environmental impacts associated with a product or service and provides a holistic approach by considering the potential impacts from all stages of manufacture, product use, and end-of-life stages.

EPDs combined with the Life Cycle Assessment approach with a level playing field provided by Product Category Rules (PCR), results in a reliable resource for the customers to have better clarity on which product to opt for.

JSW plans to institute EPD as a group-wide programme complying with EN 15804 and ISO 14025 standards.

Environment Product Declarations

Finished Steel Flat Products

JSW Steel Limited manufactures the Flat products. The steel products are produced predominantly by two process routes i.e. Blast Furnace (BF)/Basic Oxygen Furnace (BOF) route and Electric Arc Furnace (EAF) route. JSW Steel has COREX technology for steel production similar to blast furnace technology. Primary data is used for all gate-to-gate processes and iron ore mines owned by JSW Steel.

Finished Steel Long Products

JSW Steel has obtained an Environmental Product Declarations (EPD’s) – Type III eco-labelling for all finished long products from three integrated steel plants viz TMT Bar and Wire Rod from Vijayanagar, TMT Bar from Dolvi and Hot Rolled Wire Rod Coil, Heat Treated Wire Rod Coil, Hot Rolled Hexagonal Wire Rod Coil, Hot Rolled Round Cornered Square (RCS), Heat Treated Bar, Hot Rolled Bar, Hot Rolled Hexagonal Bar from Salem. This EPD is compliant with EN 15804 and is based on the LCA conducted as per the ISO 14040/44

Portland Slag Cement

Portland Slag Cement (PSC), a slag-based cement produced by JSW Cement, also has an EPD certificate. Based on the results of this EPD, JSW’s PSC has the lowest Global Warming Potential (GWP CO2eq) in the world.

Cold Rolled Closed Annealed Coil

Cold Rolled Closed Annealed (CRCA) coils produced at JSW Steel Work Vijaynagar has been awarded an EPD complaint with EN 15804 and is based on the LCA conducted as per the ISO 14040/44. The study provides a fair understanding of environmental impacts during the various life cycle stages of CRCA production.

Ground Granulated Blast Furnace Slag

Ground Granulated Blast Furnace Slag (GGBS) has been awarded an EPD compliant with EN 15804. GGBS is a unique supplementary cementitious product confirming to IS 16714:2018. It is perfect for structural concrete construction and can be used as a partial replacement of OPC in concrete production. Since it contributes towards sustainable concrete construction, GGBS is regarded as a ‘green’ building material.

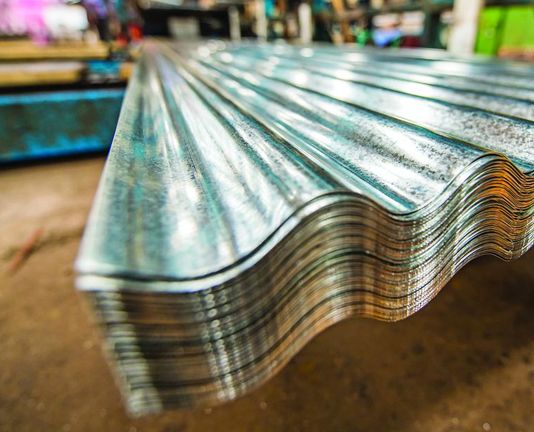

Galvanized Steel

The galvanized steel manufactured at JSWSCPL is not just high in strength, but also corrosion-resistant, durable and lightweight. The zinc-iron alloy layers formed during the process of galvanizing to create a protective coat around the steel, keeping moisture out and preventing corrosion. Galvanizing also imparts excellent adhesion and abrasion resistance, along with unmatched protection against the elements. These features make the galvanized corrugated sheets, branded JSW VISHWAS, the most sought-after in the market. It is used in roofing & cladding, structural grades, ducting, coolers, furniture and heat plates, solar heating panels, electrical & light fittings, agricultural equipments, automotive, boxes and sandwich panels etc.

Vasind: https://environdec.com/library/epd6483

Tarapur: https://environdec.com/library/epd6487

Kalmeshwar: https://environdec.com/library/epd6477

Galvalume

JSW Steel Coated Products Limited (JSWSCPL) is the first licensee galvalume producer in India that uses technology from BIEC International Inc., USA. This technology license gives the edge over others by providing continuous access to the latest product innovations and process refinements through BIEC and the ZAC Association, which enable JSWSCPL to manufacture products of the highest quality. The alloy-coated product contains 55% aluminium, 43.5% zinc and 1.5% silicon by weight.

Vasind: https://environdec.com/library/epd6484

Tarapur: https://environdec.com/library/epd6488

Kalmeshwar: https://environdec.com/library/epd6478

Pre-painted Galvanized Steel

JSW’s Colour Coated product offering combines the strength of steel, the beauty of paint and enhanced corrosion resistance in an unbeatable package. The pre-painted corrugated sheets and profiles are branded as JSW Colouron (Colour coated galvanized sheets) and JSW Colouron Plus (55% aluminium-zinc alloy colour coated steel sheets). The Pre-painted products are available in a variety of paint systems, including Regular Modified Polyester, Silicon Modified Polyester, Super Durable Polyester, Poly Vinylidene Fluoride and Vinyl Coated Metal.

Vasind: https://environdec.com/library/epd6485

Tarapur: https://environdec.com/library/epd6489

Kalmeshwar: https://environdec.com/library/epd6481

Pre-painted Galvalume

JSW’s Colour Coated product offering combines the strength of steel, the beauty of paint and enhanced corrosion resistance in an unbeatable package. The pre-painted corrugated sheets and profiles are branded as JSW Colouron (Colour coated galvanized sheets) and JSW Colouron Plus (55% aluminium-zinc alloy colour coated steel sheets). The Pre-painted products are available in a variety of paint systems, including Regular Modified Polyester, Silicon Modified Polyester, Super Durable Polyester, Poly Vinylidene Fluoride and Vinyl Coated Metal.

Vasind: https://environdec.com/library/epd6486

Tarapur: https://environdec.com/library/epd6490

Kalmeshwar: https://environdec.com/library/epd6482

Tinplate

Being non-toxic in nature and because of its ability to resist bacteria, UV radiation, retain original colour, flavour and aroma of the contents, Tinplate is extensively used as a packaging medium for storage of canned foods, juices and other beverages. Other than edibles, Tinplate has paved its way into the packaging of paints, aerosols, battery jackets, chemicals, closures, etc. It is 100% bio-degradable and 100% recyclable, and thus, a highly sustainable packaging medium.