S4

CAPITALS DEPLOYED

CAPITALS ENHANCED

US$130

Conversion cost per tonne of steel (standalone basis)

92%

Capacity utilisation

Our commitment to leveraging advanced technologies and digital tools is key to optimising resource usage, reducing costs, and improving overall productivity. Our strategic implementation of innovative solutions spans various critical areas such as supply chain management, manufacturing processes, and energy consumption. By doing so, we are creating a futureready digital workforce, and ensuring safety and sustainability in our operations.

TRANSFORM

Being future-ready through technology-led transformation and digitisation

Technology absorption,

adoption and innovation

The Maximised Emission Reduction of Sintering (MEROS) system at Sinter Plant-1 was commissioned to reduce stack emissions, aligning with Central Pollution Control Board norms. Additionally, extensive capital repairs were completed in key facilities, including cyclones, bustle mains, air compressors, and maintenance of the BLT, tuyere platform, SGP, and stoves of BF-4. The PCI of BF-1 and the SGP cranes were successfully commissioned, further boosting operational efficiency. To advance research capabilities, the R&D Department commissioned a Universal Hardness Tester and a Cyclic Corrosion Test Apparatus, demonstrating JSW Steel's commitment to continuous improvement and innovation.

Centre of Excellence

The JSW Steel Centre of Excellence (COE), established in FY 2022-23, has been pivotal in unifying and enhancing operational efficiencies and digitalisation across various locations including Vijayanagar, Salem, and Dolvi. Expanding its influence in FY 2023-24 to include downstream units and even JSW USA steel plants, the COE has driven innovation and synergistic growth by promoting a culture of collaboration and leadership. This central hub has successfully leveraged over 200,000 years of collective experience, ensuring a sustainable and innovative future for JSW Steel.

Digitalisation

The digital journey of JSW Steel has consistently delivered value through initiatives designed to reform every aspect of its operations. The adoption of the various tenets of Industry 4.0 technologies is key to driving business transformation in manufacturing, supply chain, sales and marketing, safety, and sustainability - redefining industry standards and setting new benchmarks for performance. These digitalisation initiatives are integrated deployments that collectively transform how we operate, innovate, and deliver value to our stakeholders.

Mining

Digital transformation in logistics operations within iron ore mining has enhanced our planning and operational efficiency. By embracing digitalisation across our major mines in Odisha and Karnataka, we have streamlined mine to plant logistics processes, optimised resource utilisation, and improved overall visibility leading to better planning and operational efficiency.

The use of IoT sensors, RFID tracking systems, and real-time monitoring platforms has allowed us to improve planning and disbursement of fuel for all mining equipment, leading to a significant improvement in the overall equipment efficiency in mines.

Manufacturing

The deployment of digital technologies and advance analytics has allowed us to re-imagine manufacturing unit operations through various use cases to improve quality, efficiency, safety and sustainability. Several machine learning-based models that help in optimising process parameters in blast furnace operations, reducing operational cost in pellet manufacturing units, optimising consumption of alloys in steel making operations, and assuring quality in finishing mills, are a few examples.

Process improvement efforts in manufacturing have seen the utilisation of drones for inspections, Condition-Based Monitoring (CBM) of critical equipment through Industrial IoT sensor, and edge analytics to move from preventive to reliability-centred maintenance.

Technologies such as virtual reality, computer vision and automated interlocking mechanisms by reducing man-machine interactions, have been introduced to minimise human errors and improve workplace safety.

Supply chain

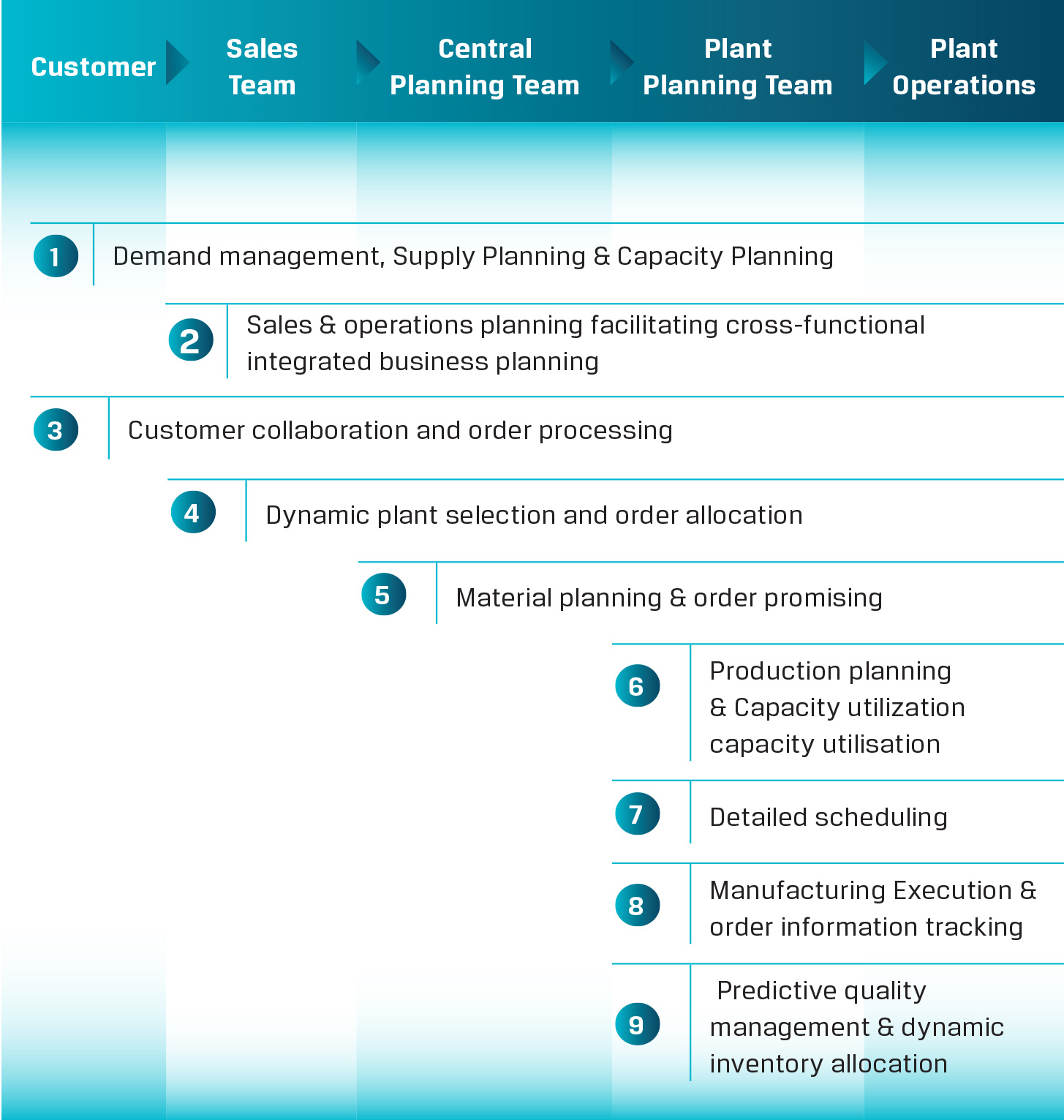

Advance Planning & Scheduling (APS) system has been implemented to provide a seamless customer experience and improve order fulfilment. By integrating customer-facing platforms with core planning systems and manufacturing execution systems, APS has enabled optimal inventory management and reduced order-to-cash cycles. Furthermore, logistics planning systems and automation of transportation management through SAMPARK programme has improved logistics efficiency to provide complete visibility of logistics operations - reducing costs and improving on-time delivery performance.

Sales and marketing

Sales and marketing efforts are also strengthened through customer experience platforms integrated with CPaaS solutions, enabling seamless communication to connect, personalise, engage, and improve customer experience. AI-driven customer engagement initiatives include the use of smart AI assistants and personalised recommendations to enhance the customer journey and drive business growth. The Customer Solution Lab was established with a state-of-the-art multimedia setup to enhance customer interactions.

Revolutionising customer interaction

The AIKYAM One View app is set to transform JSW Steel's interactions with its customers by consolidating fragmented customer interactions into a seamless, integrated experience. The AIKYAM platform will offer real-time order tracking, access to account information, real-time notifications, and efficient enquiry and complaint management.

Featuring an AI-enabled assistant, the app provides real-time support and guidance to users, ensuring a streamlined and responsive customer service experience. The AIKYAM One View app emphasises JSW Steel's commitment to enhancing customer engagement, satisfaction, and overall business performance. The app will become a focal point for all information and interactions for all JSW group business verticals in the Construction & Infrastructure segments like steel, cement, construction, chemicals and paints.

Digital capability development

At JSW, we fully recognise that digital capability development is crucial for preparing and upskilling the workforce to be future-ready. It involves providing training and resources to equip employees with the necessary digital skills and knowledge to thrive in an increasingly digitalised environment. We leverage experiential learning platforms, academic and structured classroom programmes to improve digital literacy in the organisation.

Digital empowerment

- Self-paced learning via Learning Management System/Digital Central/Percipio.

- High-level digital awareness at plant locations by introducing topics such as: Introduction to Digitalisation, IoT, Analytics, AI/ML, Digital Twin, Robotics, etc.

- In-depth Data Science training in collaboration with IIT Bombay.

- Arranging various events such as digital Xchange, Digital Confluence, visit to technology centre, etc.

Sustainability, safety, and security

We understand the importance of a sustainable supply chain. Playing a leading role in this effort, we have initiated a digitally enabled comprehensive sustainable supply chain assessment which brings all our supplier partners onto an integrated platform and enables a collaborative assessment and improvement programme to monitor and deliver on our sustainability commitment.

Digital platforms for tracking and reporting sustainability initiatives at JSW Steel facilitate data-driven decision-making and continuous improvement. Real-time monitoring systems enhance safety behavioural practices and ensure compliance with safety standards. Additionally, digital platforms for effective management of incident reporting and action tracking, audits and inspections, permit to work, change management, and contractor safety management, are in use across the steel manufacturing units.

AI-based vision intelligence systems detect PPE violations, and smart wearable devices track human movements in hazardous areas. The implementation of thermal imaging and video analytics solutions has enhanced monitoring precision and decision-making, particularly in metal sheet cutting processes.

We have introduced a smart digital solution for workforce tracking and identification through online connected access cards. These cards are equipped with multiple smart sensors that continuously monitor the workforce, ensuring constant safety surveillance of their locations and providing instant real-time alerts in the event of accidents, leading to a safer work environment.

Industry 4.0 for steel manufacturing value chain

The integration of various tenets of Industry 4.0 like AI & Machine learning, Edge Computing, Digital Twin in steel manufacturing is transforming our plants into smart manufacturing centres with the best performing indicators in Quality, Productivity, Cost, Safety and Sustainability.

Advance Planning (APS) Vision - Seamless

integration across the value chain

Outlook

Near-term

JSW Steel is focusing on leveraging AI and Industry 4.0 principles for sustainable growth in several key areas. We are prioritising process optimisation across our manufacturing facilities by integrating AI-driven predictive quality and predictive maintenance through connected and real-time monitoring systems. A well-synchronised combination of data and analytics applications will lead to improved quality, reduced costs, and maximised operational efficiency.

Additionally, we are investing heavily in predictive quality assurance to ensure the highest standards of product quality and consistency. By implementing advanced machine vision and data analytics techniques, we can detect defects early in the production process, leading to fewer rejections and improved customer satisfaction.

Long-term

Emphasis on AI-powered interventions built on our strong data infrastructure will provide an enterprise 360 view of Customer, Product and Market and will be a key competitive differentiator for the group.

Looking ahead, the extensive use of AI and smart manufacturing is promising. We anticipate increased automation, greater integration of IoT devices, extensive use of advanced data analytics-based decision making to move from reactive to predictive operations. This will enable us to stay ahead of market trends, enhance agility, and drive innovation across our operations.