231.24 billion

Cumulative saplings planted over the years

At JSW Steel, all our business operations are underpinned by a singular guiding philosophy – minimising environmental footprint and promoting ecological well-being. Recognising the critical importance of nurturing a healthy environment, we have adopted a proactive approach. Through innovation, cutting-edge technologies, operational and cultural changes, we mitigate long-term environmental risks while promoting sustainability.

Our key commitments include integrating environmental considerations into our business strategies, preventing pollution, evaluating impacts, and fulfilling all related obligations. We prioritise process and energy efficiency, resource optimisation, continuous improvement and product sustainability leading to the development of low-carbon steel grades with enhanced strength and properties. With a focus on clear decarbonisation targets, our aim is to emerge as a recognised advocate for sustainable practices within our industry. Additionally, we engage with stakeholders to foster environmental awareness and lead conservation efforts in the ecosystems surrounding our operations.

Our plant operations boast 100% coverage of the following prestigious international certifications.

Vijayanagar

Dolvi

Salem

Vasind

Kalmeshwar

Tarapur

Vijayanagar

Dolvi

Salem

Vasind

Kalmeshwar

Tarapur

Vijayanagar

Dolvi

Salem

Vasind

Kalmeshwar

Tarapur

Vijayanagar

Dolvi

Vasind

Kalmeshwar

Tarapur

Vijayanagar

Odisha Mines

Salem

We have been included in the DJSI World Index and the DJSI Index for Emerging Markets, with a 99th percentile score in the 2023 S&P Global Corporate Sustainability Assessment. This helped us achieve the second position globally in the steel sector.

Rank in the global steel industry as per the S&P Global Corporate Sustainability Assessment 2023

CDP Climate Change 2023

CDP Water Security 2023

Focus areas are supported with 2030 targets

Focus areas are supported with 2030 targets

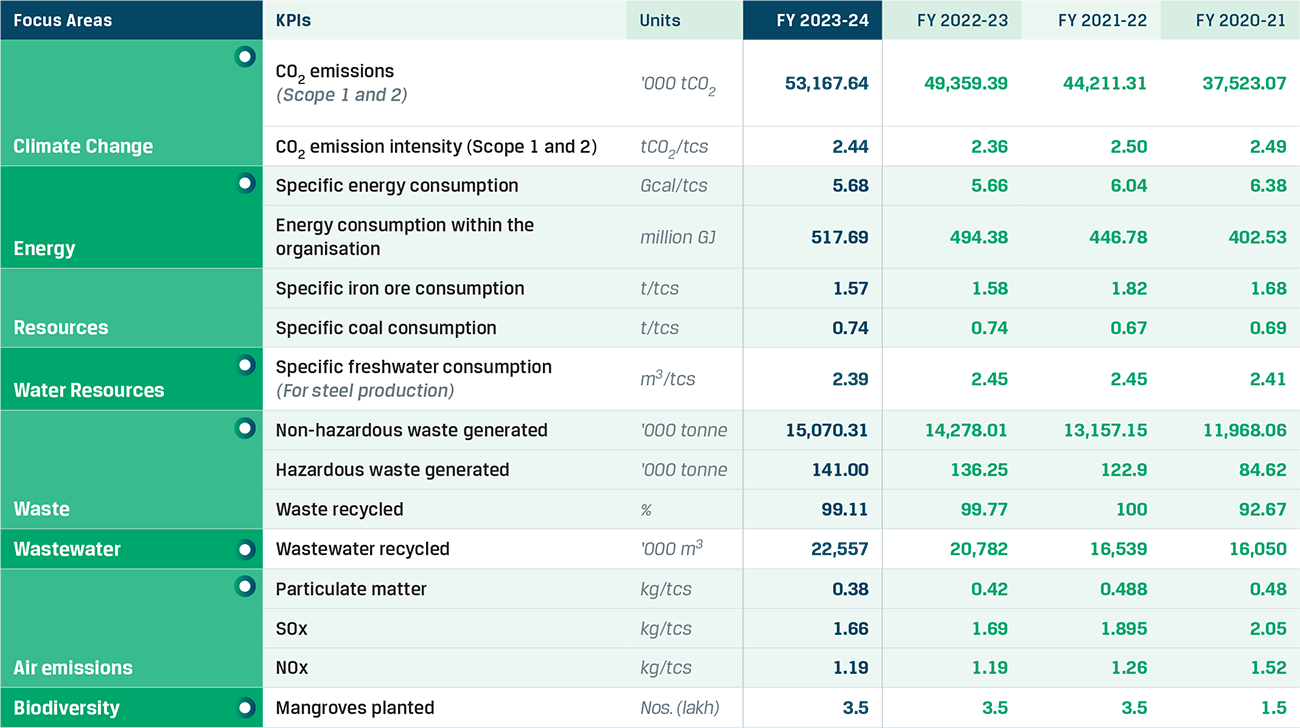

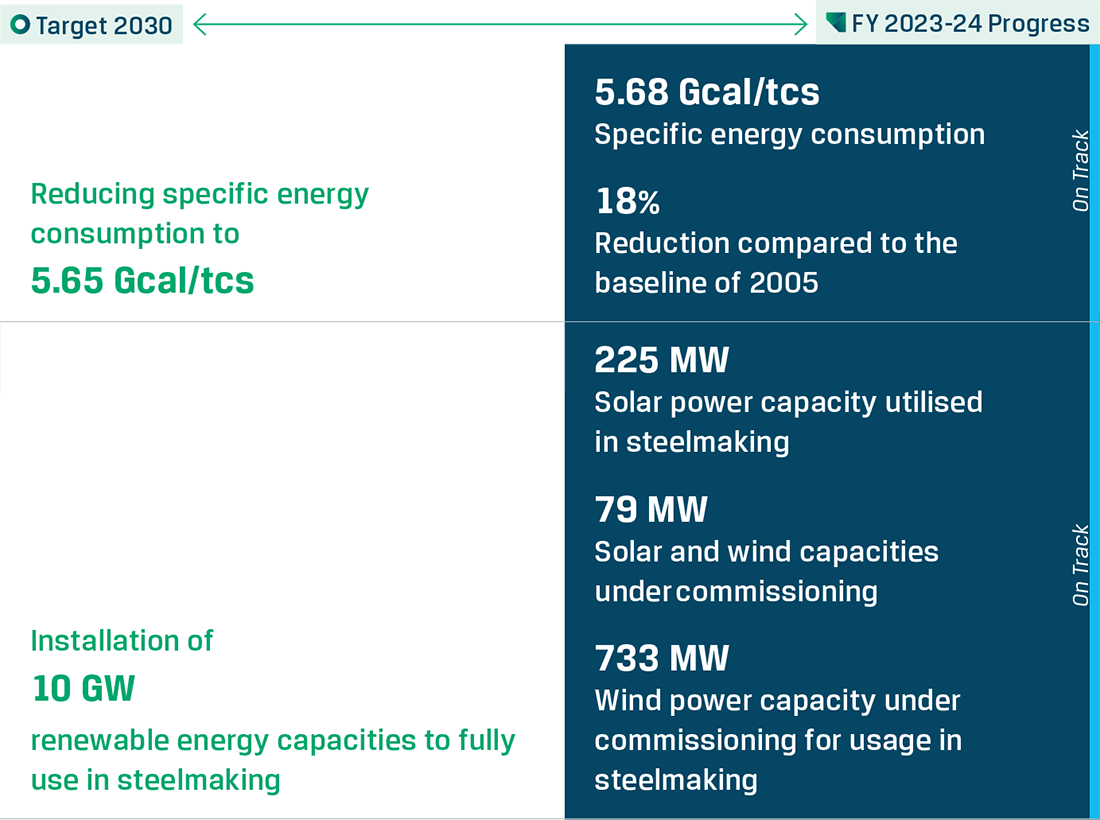

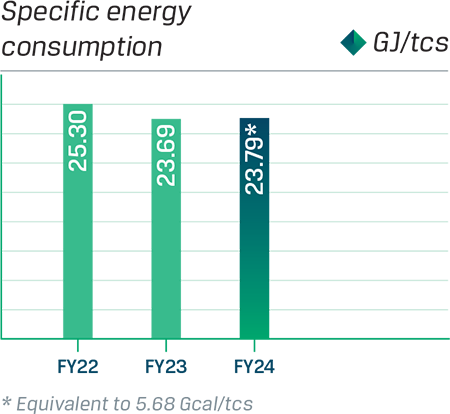

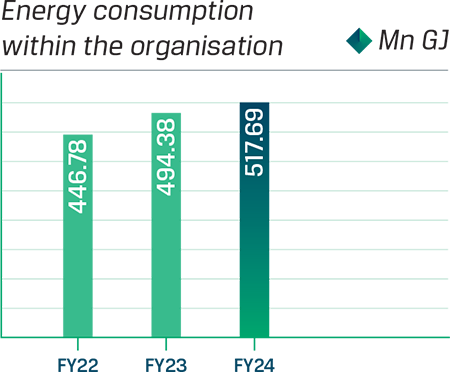

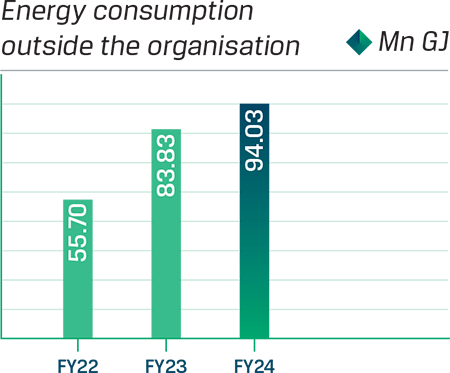

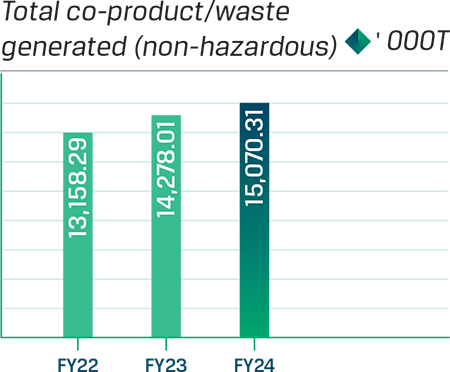

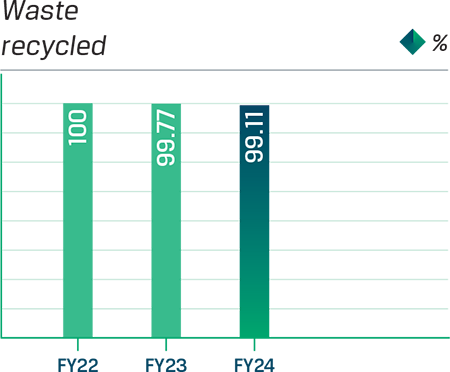

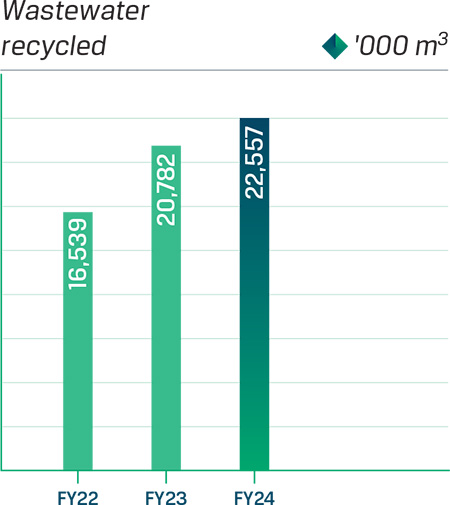

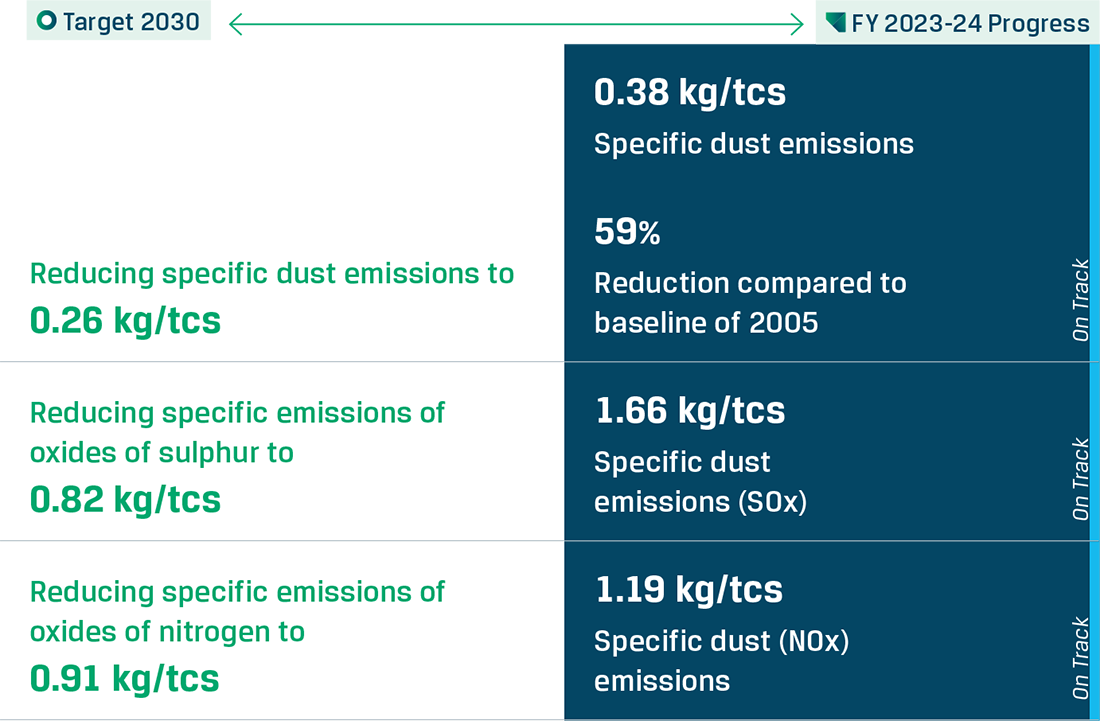

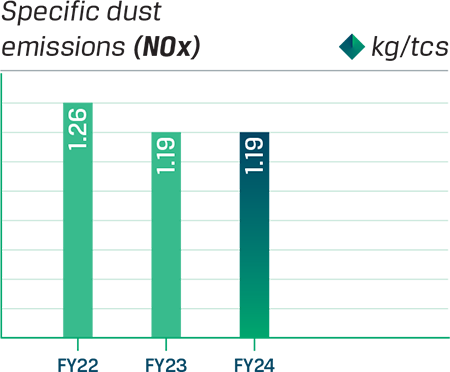

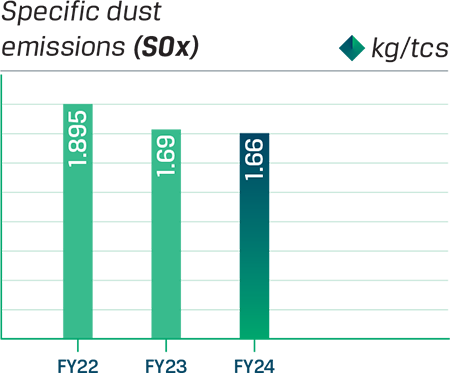

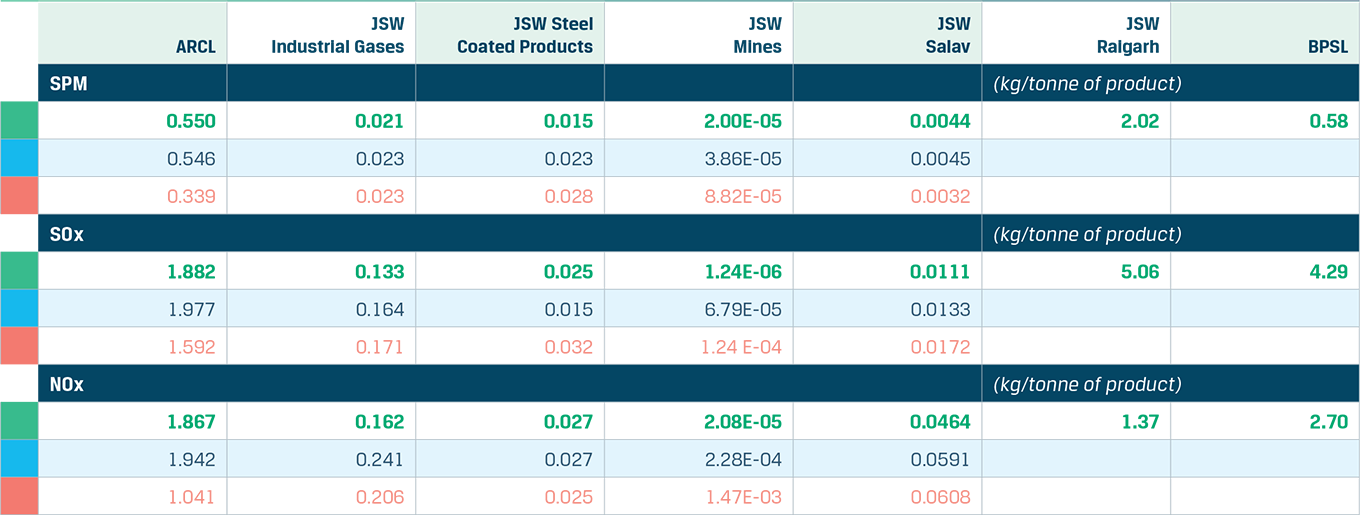

Note: All intensities are worked out with 21.76 MnT standalone crude steel production. Progress figures are for integrated operations of JSW Steel standalone, excluding Raigarh plant

1 Waste data excludes tailings

2 Non-hazardous waste diverted from disposal–14,938.53 (‘000 tonne) and hazardous waste diverted from disposal 137.88 (‘000 tonne)

3 Air emissions data are from process stacks

* Equivalent product for Vasind, Tarapur and Kalmeshwar

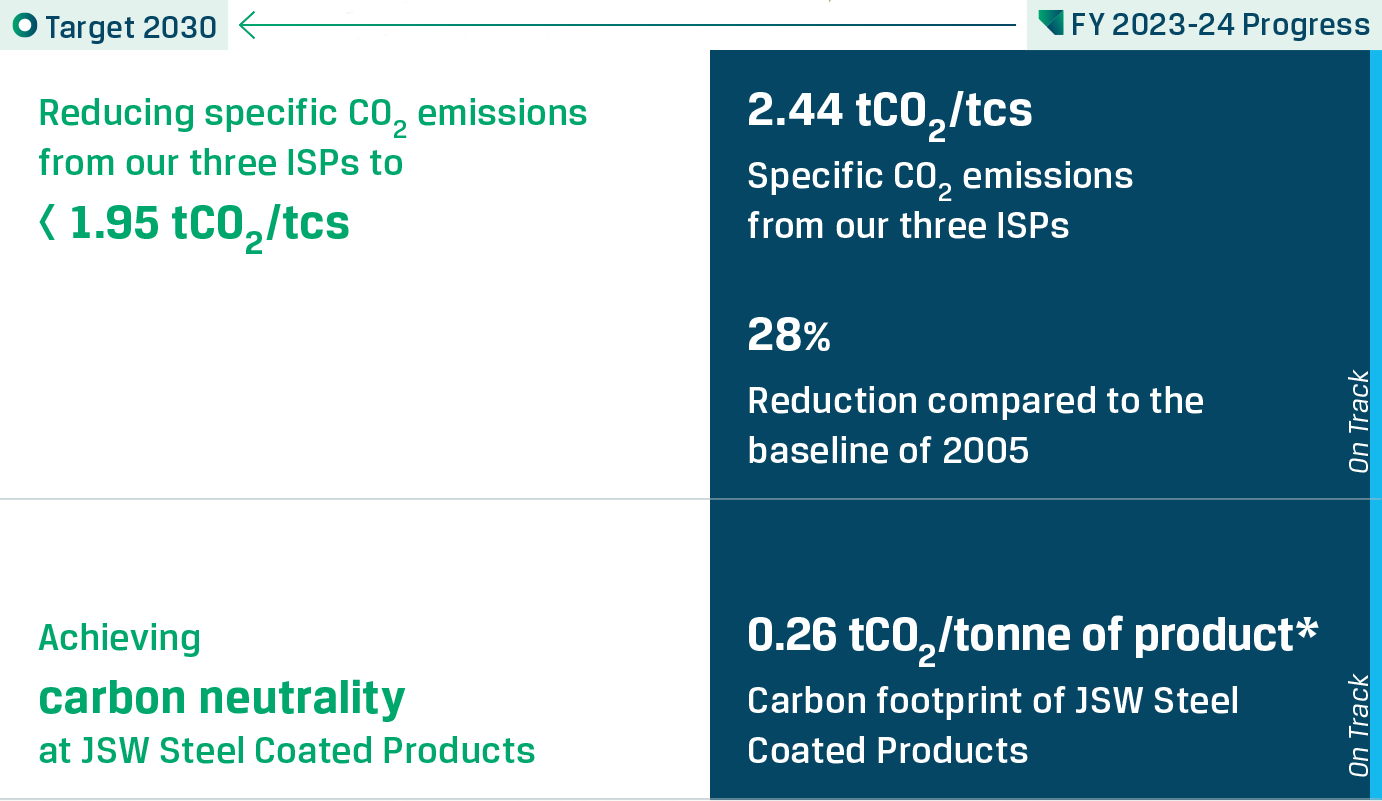

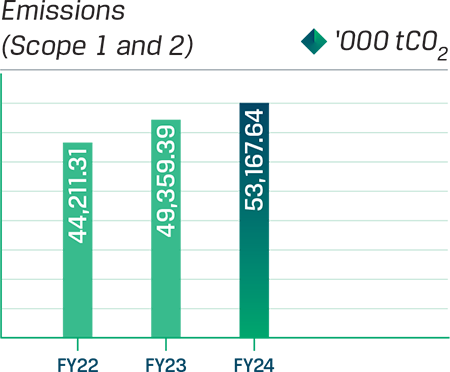

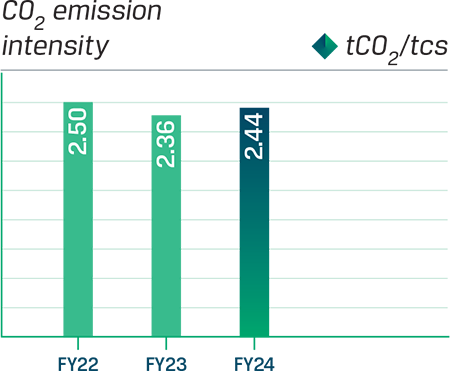

Climate change presents an unparalleled global challenge, posing a significant threat to humanity's future. This challenge, however, unfolds against the backdrop of India's rapid economic ascent. According to the National Steel Policy, India’s economic engine is expected to surge, reaching a capacity of 300 MTPA by 2030, underscoring the scale and pace of our nation's development.

As a key player in India's steel production landscape, we shoulder the responsibility of confronting climate change head on. Anchored in our commitment to forging a low-carbon future, we have embarked on a journey marked by decisive actions and strategic foresight. We have charted a comprehensive roadmap outlining our strategies and plans, positioning climate action as a cornerstone of our organisational ethos.

Climate action takes precedence within our organisational framework, underpinned by a robust climate governance structure designed to facilitate agile and effective responses. Our climate change policy is structured around three foundational pillars:

![]() Read more about our Climate Change Policy on our website

Read more about our Climate Change Policy on our website

Institutionalising our dedication, we have established a dynamic Climate Action Group (CAG), comprising experts from diverse functional domains, entrusted with spearheading our climate mitigation endeavours. Serving as the nerve centre for coordinated climate action, the CAG regularly monitors and evaluates our sustainability performance, ensuring tangible progress toward our objectives.

As the world grapples with the escalating impacts of climate change, sustainability has never been more crucial. At JSW Steel, we are rising to the challenge with an ambitious target: achieving net neutral in carbon emissions for all operations under our direct control by 2050. Recognising the urgent need to address climate change, our allegiance aligns with global efforts and resonates with the aspirations of the Paris Agreement. This initiative underscores our dedication to a sustainable future and reflects our role in the collective journey toward environmental responsibility.

![]() Refer page for our decarbonisation

roadmap and efforts.

Refer page for our decarbonisation

roadmap and efforts.

We monitor our Scope 3 emissions to gain a thorough understanding of the complete greenhouse gas impacts of our supply chain. This approach enables us to effectively oversee our environmental impact and actively pursue strategies aimed at diminishing our overall carbon footprint.

During the reporting period, we had a credit due to avoided emissions of about 5.25 million tCO2 in the categories of Use of Sold Products and Processing of Sold Products, as per the guidance of Worldsteel.

The following categories contributed around 12.22 million tCO2 emissions:

The Scope 3 emissions of all applicable categories were calculated in accordance with the technical guidance for calculating Scope 3 emissions issued by the GHG protocol.

Recognising the collective effort needed to combat climate change, we partner with academia and industry to develop scalable solutions. We are actively involved in initiatives and alliances such as the International Renewable Energy Agency (IRENA), India Hydrogen Alliance (IH2A), World Steel Association, Science Based Targets initiative (SBTi), United Nations Global Compact (UNGC), Responsible Steel, World Business Council for Sustainable Development (WBCSD), Task Force on Climate-related Financial Disclosures (TCFD), Climate Action Charter, Global Reporting Initiative (GRI), and Indian Business Biodiversity Initiative (IBBI). Additionally, we are founding members of EV100+, an initiative aiming to phase out heavy-polluting vehicles. We also collaborate with various companies to enhance energy efficiency and explore cutting-edge climate technologies.

We acknowledge the global challenge of climate change and have committed to reducing our emissions to contribute to its mitigation. In March 2021, we pledged to adopt and uphold the recommendations of the TCFD. By aligning with these recommendations across its four pillars, we aim to enhance our understanding of climate change impacts and make informed decisions on current and future decarbonisation strategies.

We released our first Climate Action Report. The key aim of this Report is to present in an engaging and informative manner our challenging decarbonisation strategy and the actions into which that strategy translates.

This Report demonstrates our alignment to recommendations of the TCFD and provides stakeholders with: ‘clear, comprehensive, high-quality information on the impacts of climate change’. It addresses the four thematic areas of the TCFD: Governance, Strategy, Risk Management, and Metrics and Targets.

The Climate Action Report describes in detail the scenario analysis approach used to test the resilience of our organisation’s preparedness against different climaterelated physical and transition risks and identify business opportunities.

In FY 2023-24, we published our first Climate Action Report, marking a significant milestone in our sustainability journey. This report provides a comprehensive overview of our actions, strategies, and commitments towards combating climate change.

![]() Read the Report on our website

Read the Report on our website

Interventions

Outcomes

Sustainable Energy Environment and Decarbonisation

In FY 2022-23, we embarked on a bold mission to fast-track the achievement of our decarbonisation commitments for 2030, with the launch of Project SEED (Sustainable Energy Environment and Decarbonisation), our flagship decarbonisation programme at Vijayanagar. This plant-wide programme, involving members from various shops, was a resounding success, paving the way for Vijayanagar’s accelerated decarbonisation journey.

Now nearing completion of its second year, Project SEED has been horizontally deployed at our Dolvi operations. As part of the programme, we are developing detailed shop-specific climate action plans with clear emission baselines, targets, and prioritised initiatives. The programme also aims to drive organisation-wide engagement on the climate agenda right at the shop floor, with employees participating in bottom-up divergence workshops conducted across the plant.

Over the past year, significant strides have been made through the execution of nine comprehensive workshops across various departments, engaging over 200 attendees. These workshops facilitated the identification and initiation of more than 175 initiatives, spanning critical areas such as fuel and power consumption reduction, waste heat recovery, circularity, alternate fuels, digital analysis, renewable energy integration, and scrap charging. Furthermore, we established 10 Climate Action Centres to provide focal points for sustainability initiatives across our operations. In line with our commitments, 20 initiatives were successfully implemented in the reporting year, resulting in 60 kg/tcs of CO2 emissions reduction.

Our innovative approach to sustainability has been recognised, with Project SEED honoured as one of the top Global Energy Transition Changemakers at COP 28. Additionally, our decarbonisation journey has attracted attention beyond our industry, with our strategies becoming the subject of a Harvard Business School case study, highlighting our unique and effective methodologies. These accolades, along with other recognitions underscore our commitment to responsible business practices and our leadership in driving positive change within our industry and beyond.

Potential abatement by 2030

The global momentum towards sustainable energy is fundamentally changing how we power our world. For businesses entrenched in traditional non-renewable energy models, this transition is both a challenge and an unprecedented opportunity for innovation and growth.

Amid rising energy costs and increasing societal demands for a better quality of life, securing access to economically viable and environmentally sustainable energy solutions are imperative.

We are actively engaged in the strategic integration of renewable energy sources into our operational framework and exploring innovative avenues to incorporate clean energy solutions into every facet of our business, from manufacturing processes to logistics. By optimising our energy footprint and embracing renewables, we are mitigating our environmental impact while future-proofing our business against volatile energy markets and regulatory uncertainties.

Accelerating renewable energy transition

We entered into a Power Purchase Agreement (PPA) for procuring 958 MW of renewable power (RE) in FY 2021-22. Out of the total 958 MW of RE, solar capacity of 225 MW was commissioned at Vijayanagar in FY 2022-23, with the remaining 733 MW of wind power set to be progressively commissioned by FY 2024-25 across various plant locations. Additionally, contracts for 79 MW (solar and wind) capacities at our plants have been secured for commissioning by FY 2025-26. The Board of Directors has approved entering into a contract for procuring a hybrid renewable energy generation capacity of 600 MW (200 MW solar and 400 MW wind), along with 320 MWh battery storage at Vijayanagar, scheduled for commissioning by FY 2026-27. All these renewable capacities are being set up under the group captive norms prescribed under the Electricity Act.

Interventions

Outcomes

In pursuit of enhanced energy efficiency, we launched a project aimed at optimising LD gas recovery at the Basic Oxygen Furnace (BOF) in our steelmaking shop. Our objective was to reduce CO2 emissions at the flare stack during the gas recovery process.

The project prioritised maximising LD gas recovery during blowing conditions by capturing it in a gas holder. During blowing conditions, based on the calorific value of CO, LD gas is captured in a gas holder if CO exceeds 30% and O2 is below 0.2%. However, the limited storage capacity of the gas holder required a re-evaluation of design parameters to optimise LD gas flow.

An internal design modification was devised and implemented to enable online cleaning of the mesh, which often became clogged with dust particles, hindering gas flow from the gas holder. Additionally, three booster fan operations were introduced to facilitate the efficient transfer of LD gas into the network.

These interventions yielded significant improvements in LD gas recovery and utilisation. The average specific gas utilisation increased by more than 17%, representing a notable enhancement in operational efficiency. The project also resulted in substantial fuel and energy savings, amounting to 157,667 kNm3 and 301,460 Gcal, respectively.

Moreover, the increase in specific LD gas utilisation translated to a considerable reduction in CO2 emissions. By maximising gas recovery, we achieved a reduction of 53,134 tonnes of CO2 emissions per year, equating to a reduction of 5 kgCO2/tcs.

Through this project, we have not only reduced operational costs but also significantly mitigated our carbon footprint, demonstrating the potential of innovative solutions in advancing towards a sustainable future.

A critical aspect of energy conservation is the management of steam systems. Steam is widely used for various processes, but its efficient utilisation is often hindered by issues such as the passage of water and non-condensable gases in steam lines. These issues not only lead to the underutilisation of heat in processes but also pose risks such as water hammer and equipment damage. However, these challenges can be addressed through the strategic installation and maintenance of steam traps, minimising energy waste and maximising productivity.

Steam traps are automatic valves designed to discharge condensate and air while retaining live steam, and have been identified as being instrumental in maintaining optimal conditions within the steam system. A total of 250 steam traps were initially installed across different units within the plant at our BPSL operations. These traps were strategically placed to address specific points of condensate and air accumulation, ensuring efficient removal while minimising steam loss.

Moreover, a proactive approach was adopted to continually identify new requirements and install additional steam traps as needed. A robust inspection regimen has been implemented to monitor the performance of existing steam traps and promptly identify any malfunction or inefficiencies.

By effectively removing condensate and air from the steam system, the installed steam traps help to maintain optimal temperature and pressure conditions, leading to improved energy efficiency in steam-based processes while also extending the lifetime of critical steam system components. The efficient operation of these systems also contribute to a reduction in energy consumption throughout the plant, leading to lower CO2 emissions.

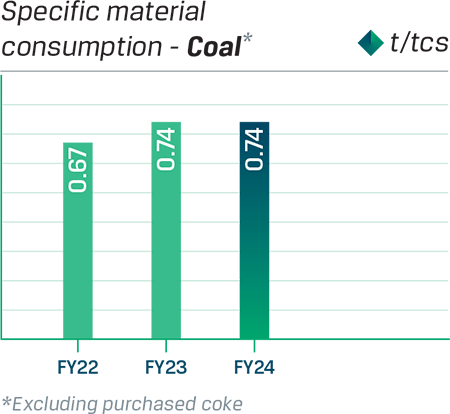

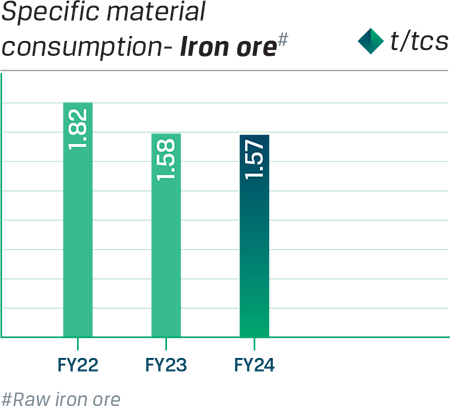

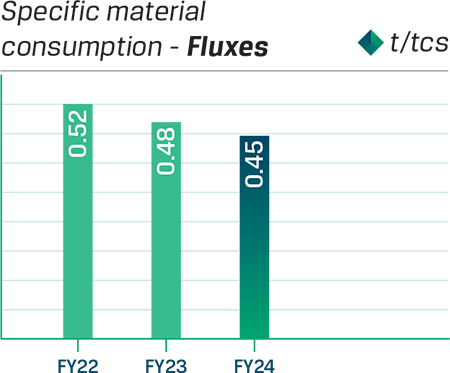

As global economies and populations grow, the demand for natural resources is reaching unprecedented levels. This surge intensifies competition among industries and nations, highlighting the critical need for conscientious and sustainable sourcing methodologies to ensure long-term resource security.

Recognising the urgency of these challenges, we have proactively integrated sustainable practices into the core of our operations. We are dedicated to optimising resource allocation, minimising dependence on finite resources and exploring innovative approaches to material reuse and recycling.

We champion the principles of a circular economy, advocating for a paradigm shift where resources circulate within a closed-loop system, thus minimising waste generation and maximising resource efficiency. At the heart of our resource conservation strategy lies a holistic approach that includes careful sourcing, prudent utilisation, and strategic initiatives aimed at reducing the demand for raw materials.

Interventions

Outcomes

Blast furnaces generate a significant amount of blast furnace (BF) gas as a by-product. Historically, this has resulted in considerable energy loss, increased CO2 emissions, and financial costs for the organisation.

To address these challenges, we have implemented innovative solutions to efficiently utilise this waste gas. One such solution is the use of dual-fired boilers, which leverage fluidised-bed combustion technology to improve efficiency while burning solid fuels. A 250 TPH dual-fired boiler was commissioned at our BPSL operations in the reporting year.

The dual-fired boiler provides fuel flexibility, enabling the combustion of various challenging materials such as biomass or waste fuels. Unlike conventional systems, which struggle with low calorific value, volatile matter, or high moisture content in solid fuels, the fluidised-bed combustion technology efficiently burns these materials.

By utilising the dual-fired boiler, we have effectively utilised BF gas as a secondary fuel, thereby reducing energy losses and operational costs. The implementation of this technology will eventually result in significant energy savings, estimated at approximately 8,56,800 Gcal per annum. Furthermore, it will lead to an overall reduction in CO2 emissions by approximately 8,87,000 tCO2.

By leveraging this innovative technology to maximise fuel flexibility and minimise energy losses, we also achieved a reduction in specific coal consumption, thereby reducing our dependency on fossil fuels and making significant strides towards increased resource efficiency.

We operate a captive thermal power plant at our Salem Works to meet the power demands of our steel manufacturing facility. However, the increased reliance on coal in our boiler system contributes to greenhouse gas emissions and depletes finite fossil fuel resources, exacerbating climate change impacts.

To mitigate these environmental impacts, we initiated a project to substitute a portion of coal usage with biomass sourced from local suppliers. Selection criteria for biomass included its impact on boiler operation, ease of handling, preparation requirements, energy efficiency and quality.

Despite challenges in increasing the percentage of biomass briquettes in the blend, the team explored alternative options such as agro-waste materials like spent coffee grounds, coffee husk, veneer chips, cattle dung cake, rice husk, wood chips, bio-char and corn cob. After a thorough feasibility study, several types of biomass were identified and integrated into the boiler system alongside coal and biomass briquettes. The calorific value of the selected biomass ranged from 2,200 kcal/kg to 3,800 kcal/kg.

Prior to implementation, a comprehensive risk assessment using the Process Decision Programme Chart (PDPC) was conducted. Two primary risks were identified: charging of biomass and screening of biomass.

The presence of a grid in the hopper caused delays in charging biomass of varying weights and sizes, resulting in interruptions. Mitigation measures included redesigning the hopper for easier discharge and introducing a feeder for quicker biomass charging, while maintaining separate processes for coal and biomass charging.

For the screening of biomass, fixed screen sizes designed for coal posed difficulties in effective screening. This challenge was addressed by adjusting screen aperture sizes to optimise fuel feeding times.

The implementation of this project yielded significant results, achieving a biomass utilisation rate of 5.10% in the reporting year, and reducing CO2 emissions by 8,081 metric tonnes. Through strategic analysis, robust designing, and effective risk management, we have successfully reduced our reliance on fossil fuels while simultaneously mitigating GHG emissions.

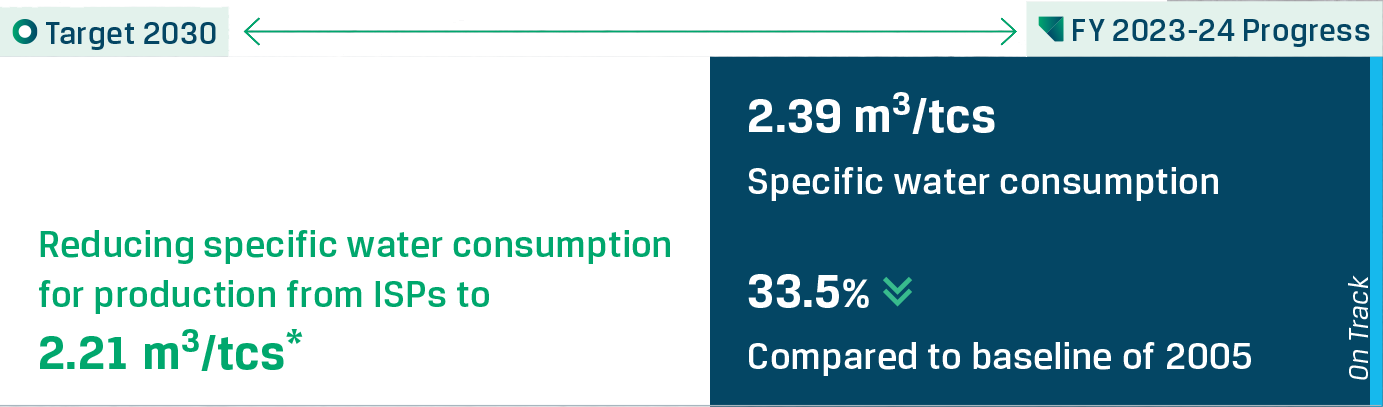

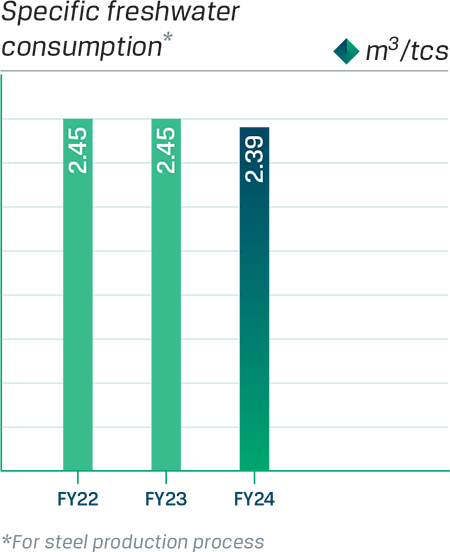

The depletion of our planet's vital water resources is escalating to critical levels, posing a significant threat to life. To tackle these challenges, innovative strategies are urgently needed to sustainably procure and manage water resources.

Our plants operate in water-stressed areas, making it crucial for us to continue pushing the boundaries in establishing long-term water security for both our operations and communities. Recognising the critical significance of water, especially in sustaining our operations, our water stewardship ethos revolves around meticulous sourcing and efficient water use.

Each of our facilities adheres to a meticulously crafted water management plan, curated with strategic foresight. We have implemented a range of conservation measures, spanning from localised aquifer mapping to comprehensive hydrogeological assessments, aimed at enhancing the judicious management of our water assets.

We have been recognised for leadership in corporate transparency and performance in water security by global environmental non-profit CDP, securing a place on its annual ‘A List’. We are among one in three companies from India, and the only steelmaker globally, to achieve an A score this year.

Interventions

Outcomes

Our Vijayanagar plant has launched a comprehensive water stewardship initiative aimed at maximising effluent treatment and increasing the use of treated water from sewage treatment plants. This approach includes immediate actions and long-term technological advancements to conserve and recycle water resources.

Currently, our efforts are focused on enhancing effluent treatment and increasing the use of treated water from sewage treatment plants. This includes reusing secondary water and minimising process losses. We are addressing water leakage and seepage to prevent wastage and improving RO system efficiency. We are also implementing measures to control and reduce wastewater discharge as well as maximising recycling from guard ponds. By conducting water audits, we further identify areas for improvement.

These efforts have reduced freshwater consumption by approximately 2,500 m3/day in process units, mainly through efficient reuse of process blowdown water. Process effluents are collected and settled in three separate guard ponds, with the water reused in secondary processes and horticultural activities.

RO plants have been installed at various sites to efficiently reuse and recycle process effluents, significantly decreasing freshwater use. Sewage water is treated through our sewage treatment plant and utilised for both RO feed and horticultural purposes.

To optimise wastewater discharge, we are minimising discharge and maximising recycling. This involves improving the Cycles of Concentration (CoC) in our cooling towers to reduce wastewater blowdown, lowering filter backwash frequency, and increasing the use of guard pond water in processes. We are also exploring using wastewater in secondary processes to replace freshwater.

By implementing treatment and recycling facilities, we have achieved Zero Liquid Discharge, with approximately 42,850 m3/day of effluent re-circulated and reused at the plant. Desilting one guard pond has enhanced its capacity, improving effluent neutralisation and supporting increased secondary usage.

Going forward, our short-term goals include streamlining processes for efficient water use, implementing advanced RO technology for better water treatment, and expanding guard pond capacity for maximum water retention. Through continuous innovation and a holistic approach to water stewardship, we aim to set new standards in responsible water management within the industrial sector, safeguarding valuable resources for future generations.

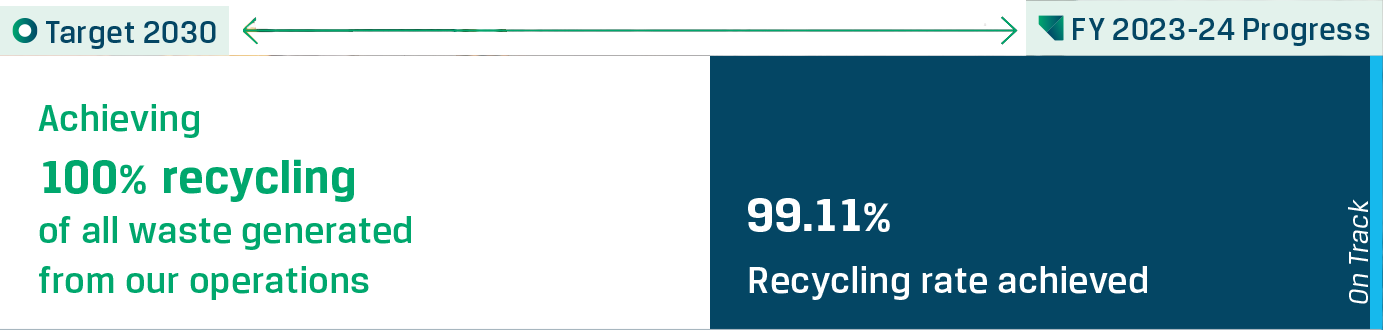

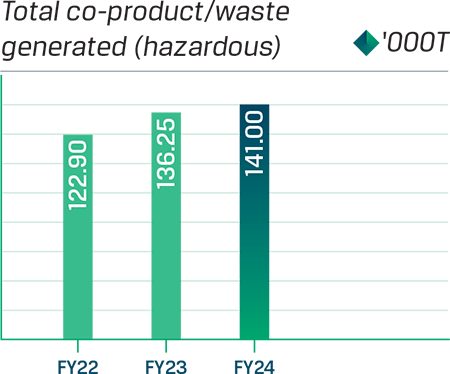

The growing global population and urbanisation have propelled waste generation, posing multifaceted threats to human health, environmental stability, and economic resilience. To address this issue, minimising waste and advocating for circular economy paradigms - which emphasise reuse, recycling, and responsible manufacturing - are paramount. Mismanagement of waste can lead to numerous problems, including organic decay contributing to GHG emissions and the accumulation of non-biodegradable waste within ecosystems.

Our integrated waste management strategy takes into account environmental impact, social ramifications, and commercial viability. Aligned with the widely accepted 'waste management hierarchy', our approach follows a sequence of prevention, reuse, recycling, and disposal. Additionally, we have adopted a 'Zero Waste to Landfill' ethos, which involves vigilant monitoring and optimising resource utilisation, alongside exploring alternative applications for waste generated.

We have embraced circularity as a transformative solution, pivoting away from conventional linear consumption patterns. Numerous innovative projects rooted in circular principles have been launched, ranging from utilising steel slag in road construction to plastic injection in BF and SMS processes, and repurposing slag for paver block production.

Interventions

Outcomes

Dry pit slag, a by-product of iron-making processes, presents a unique opportunity for sustainable resource utilisation in civil engineering applications. The slag is formed through the uncontrolled rapid cooling of molten slag in water or with the combination of steam in a separate pit adjacent to the blast furnace. Once solidified, it exhibits a wide range of sizes.

Detailed characterisation studies and lab-scale experiments were undertaken to assess the viability of dry pit slag as civil aggregates. These studies aimed to understand its physical properties and suitability for various applications. Through meticulous testing, it was determined that dry pit slag aggregates exhibit physical properties akin to natural aggregates, with bulk density and specific gravity meeting established standards. However, attention was required to address water absorption and abrasion resistance, crucial factors in determining aggregate performance.

A pivotal aspect of this project involved developing a customised screening and shaping process to convert raw dry pit slag into suitable aggregates. Drawing from lab-scale results, full-scale experimentation was conducted in a modified stone-crushing plant. This process yielded aggregates of varying sizes, including 40 mm, 20 mm, 10 mm, and sand. Subsequent cube tests confirmed the superior strength of concrete utilising dry pit slag aggregates compared to traditional natural aggregate concrete.

Dry pit slag aggregates offer several advantages over conventional alternatives. They are free from hazardous materials and possess uniform characteristics, making them ideal for concrete applications. Their angular shape and minimal surface pores enhance concrete properties, facilitating better aggregate interlocking and improved strength. Concrete made with dry pit slag aggregates demonstrates superior performance, showcasing enhanced rut resistance and durability.

The successful development of dry pit slag aggregates has led to their adoption in various civil engineering projects. JSW Vijayanagar Works has embraced this innovation, incorporating processed dry pit slag aggregates in numerous foundation and road works. This initiative has not only reduced reliance on natural stone aggregates but has also contributed to sustainable resource utilisation.

In FY 2023-24, 2.7 lakh tonnes of dry pit slag was converted into aggregates, underscoring the scalability and practicality of this approach. The transformation of this industrial by-product into a valuable resource for civil engineering applications truly highlights our commitment to sustainable waste management and the circular economy model.

The untreated discharge of industrial waste, effluents, and domestic sewage poses a threat to both natural ecosystems and human communities. The latest United Nations World Water Development Report underscores this concern, indicating that as of 2022, approximately 2.2 billion people lacked access to safely managed drinking water. Additionally, a substantial volume of wastewater is discharged into ecosystems without proper treatment or reuse, exacerbating existing challenges.

To effectively address this issue, industries must adopt a responsible approach, ensuring the proper management of effluents to limit the discharge of harmful substances into natural water bodies. At our steel manufacturing facilities, we are deeply committed to maintaining our Zero Liquid Discharge (ZLD) status.

Furthermore, we operate on-site Sewage Treatment Plants (STPs) to efficiently manage domestic sewage. Our STPs are designed to ensure that wastewater undergoes proper treatment, enabling us to repurpose the treated water effectively.

Interventions

Outcomes

In Salem Works Vacuum Degassing (VD) units, steam used for creating a vacuum is condensed into hot water using condensers. Cold water is sprayed at the top of these condensers, causing the steam to condense. This hot water is then passed through sand filters and cooled down using cooling towers. To maintain water quality, the sand filters undergo backwashing every day, consuming an average of 50,000 litres of water per day. We replaced 50,000 litres/day of freshwater used for VD filter backwash with treated wastewater from the guard pond. Risks like pipeline modifications and water quality deterioration were mitigated through parallel pipelines, isolation valves, and daily water quality analysis. By substituting freshwater with treated wastewater, we reduced our freshwater footprint, contributing to sustainable water management and resource conservation.

We are committed to combating air pollution by optimising our operations and curbing emissions. Our strict adherence to emission regulations ensures that our emissions consistently meet legal standards, with a continual proactive drive to surpass these benchmarks.

Through the implementation of a diverse range of policies and procedures, we actively work to prevent, control, and mitigate air emissions. Our efforts are concentrated on reducing both point-source emissions, such as those from stacks, and non-point source emissions, such as fugitive emissions. To facilitate this, we have established robust monitoring systems and deployed cutting-edge emission reduction technologies.

In our ongoing pursuit of enhanced emissions control, we have integrated stateof-the-art systems like the MEROS (Maximised Emission Reduction of Sintering) system into our manufacturing facilities. This advanced technology specifically targets emissions from the sintering process, a notable contributor to air pollution. Additionally, we have made significant investments in advanced scrubbing, dedusting, and filtration systems to further minimise emissions.

Covered storage for raw materials at Dolvi

In response to the growing need for sustainable practices in the handling and storage of raw materials, we embarked on a project to significantly expand and enhance our covered storage infrastructure at Dolvi. This initiative aims to mitigate the environmental risks associated with open storage and promote efficient material handling practices.

With a total capacity of approximately 7,75,000 MT, the project involved the construction and conversion of various covered storage facilities to accommodate different types of raw materials, including coal, iron ore, fluxes, and pellets.

These facilities provide protection against environmental factors such as rainwater contamination, and minimise fugitive emissions during material handling operations. Preventing rainwater contamination ensures the preservation of water quality, protecting aquatic ecosystems. By transitioning from open storage to covered sheds, we aim to eliminate material spillage on roads and prevent dust emissions, thereby contributing to a healthier and cleaner environment for both employees and local communities.

Interventions

Outcomes

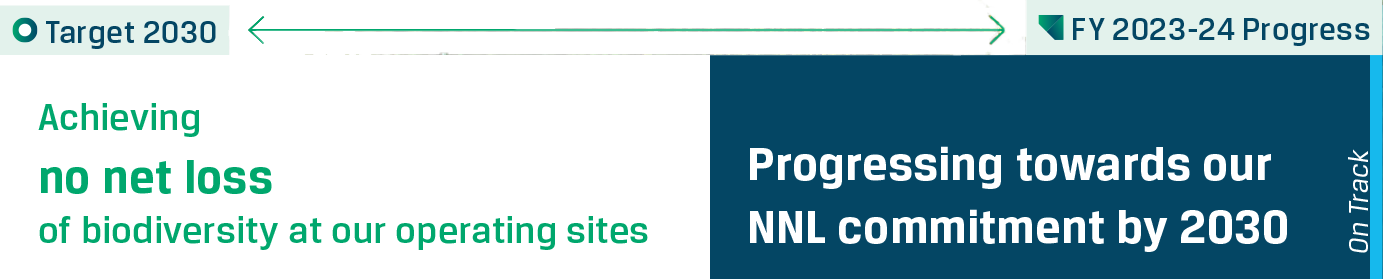

Preserving biodiversity is essential for maintaining ecological balance, and this is a key focus area recognised by the World Business Council for Sustainable Development (WBCSD).

At JSW Steel, we place significant emphasis on biodiversity conservation. We have aligned ourselves with National Biodiversity Targets and adopted a riskbased approach, integrating biodiversity considerations into our decision-making processes. As a proud founding member of the India Business and Biodiversity Initiative (IBBI) Chapter of Confederation of Indian Industry - Centre of Excellence for Sustainable Development (CII-CESD), we actively advocate for biodiversity conservation within the business community.

To protect biodiversity, we have implemented proactive measures. We conduct thorough analyses of our operations' biodiversity impact within designated zones, and we implement scalable strategies for its protection. Through collaboration with local communities, we lead initiatives aimed at revitalising natural habitats and reducing biodiversity loss.

A notable example is our application of scientific management practices to protect the mangrove ecosystem adjacent to our Dolvi facility, effectively shielding farmlands from saltwater encroachment while facilitating the restoration of natural vegetation.

Mangroves saplings planted

Cumulative saplings planted over the years

Area covered by mangrove plantation

Cumulative area restored over the years

Interventions

Outcomes

We are committed to promoting biodiversity conservation through efforts focused on increasing green cover and fostering environmental sustainability through plantation and afforestation drives across both direct and indirect impact zones.

To rapidly restore and enhance green cover at our Salem operations, we undertook the Banapuram plantation drive using the Miyawaki method. This innovative approach creates small, dense patches of forests within a short timeframe, effectively contributing to biodiversity conservation. By nurturing these small forests, the initiative aims to regulate the microclimate of the region and provide livelihood opportunities for local communities. As part of this initiative, 1,200 trees were planted across an area covering six acres.

Plantation drives are fundamental to environmental sustainability, offering numerous benefits. Carbon sequestration, achieved through trees acting as carbon sinks, aids in mitigating climate change impacts. Furthermore, planting diverse species supports biodiversity conservation, maintaining ecosystem balance and fostering the proliferation of flora and fauna.

The Banapuram initiative brought together local communities, instilling a sense of ownership and pride in environmental stewardship. By planting climate-resilient tree species, ecosystems are better equipped to adapt to changing environmental conditions, enhancing their resilience to extreme weather events. While the initial plantation marks a significant step, true success will be realised as these plants mature into thriving forests, yielding lasting benefits for both biodiversity and society.

We recognise the critical role of responsible mining in sustainable development. Without proper management, mining can have significant environmental risks due to its reliance on natural resources. Currently, we operate 13 iron ore mines in Karnataka and Odisha, where sustainable practices are prioritised to minimise environmental and social impacts.

We are committed to minimising our environmental footprint and following responsible mining practices. Measures such as wet drilling and dust extraction systems ensure good air quality, while comprehensive surface water management structures help prevent water pollution. Additionally, our collaboration with the Central Research Institute for Dryland Agriculture (CRIDA) has enabled us to develop effective soil conservation strategies.

Biodiversity protection is also a top priority, reflected in our robust wildlife management plan implemented across our mining operations.

Our tailings management area, situated on the eastern boundary of the Vijayanagar plant, includes a well-maintained tailings pond that receives low-grade iron ore tailings from the beneficiation plant. These tailings, transported in slurry form via pipeline, are securely stored within the lined pond. Any excess water, known as supernatant, is carefully redirected back to the beneficiation plant for reuse.

Constructed upon a geosyncline, featuring a solid and impermeable rock bottom, our project site has undergone rigorous testing, including geophysical, hydrogeological, and Toxicity Characteristic Leaching Procedure (TCLP) assessments, as well as an Environment Impact Assessment (EIA), to ensure its safety and environmental compatibility.

Collaborative efforts have led to the construction of bunds with pre-engineered designs and water recovery facilities to prevent seepage, with a base made of High-Density Polyethylene (HDPE) for enhanced stability.

The pond complex consists of three ponds: Pond 1, currently being emptied with a dredger, sends retrieved paste to the Slime Recovery Plant (SRP) for >45% Fe-bearing material, which is then sent to the Pellet Plant for pelletisation, while Pond 2 receives tailings with <45% Fe from the SRP. Pond 3 receives tailings directly from the ore beneficiation process, where they undergo thickening for paste transportation, with subsequent dewatering to further fortify the bunds' stability.

Interventions

Outcomes

Steel manufacturing involves intricate processes that result in substantial levels of noise, dust, emissions, and odours, posing potential challenges to nearby communities. Recognising our responsibility as a corporate entity, we prioritise the minimisation of any adverse effects stemming from our operations on the local environment.

To uphold this commitment, we have devised a comprehensive approach, spanning four key pillars: identification, prevention, engagement, and surveillance. Through these avenues, we actively tackle pertinent concerns raised by our stakeholders, ensuring our operations align with environmental stewardship and community well-being.

Interventions

Outcomes

Despite its climate benefits, the energy transition is not without challenges, one of which is the substantial amount of land needed to set up renewable energy projects. At our captive 225 MW solar power plant, we recognised the imperative to advance renewable energy while also addressing the challenges associated with land use. We are committed to advancing the principles of a, Just Transition, and to that end, we have implemented an innovative Agrivoltaic Farming project in Vijayanagar.

Agrivoltaics leverages the shaded space beneath solar panels to cultivate crops, effectively utilising land for dual purposes: renewable energy generation and agriculture. By integrating agriculture with solar energy infrastructure, we aimed to enhance land-use efficiency while contributing to food security and sustainable energy production.

In our Agrivoltaic Farming project, solar panels were strategically positioned approximately 2 metres off the ground to create shaded areas suitable for crop cultivation. This design provided an ideal environment for plant growth, offering protection from adverse weather conditions.

A diverse range of crops including brinjal, tomato, groundnuts, and okra were selected for cultivation under the project. These crops were chosen based on their compatibility with partial shade conditions and their suitability for local consumption.

One of the significant outcomes of this initiative was the contribution to local communities. The harvested crops from the Agrivoltaic Farming plantations were donated to nearby communities. This aspect underscores the dual impact of Agrivoltaic Farming, addressing both energy and food security challenges.

To address the pressing challenges of waste management while fostering sustainable practices and community engagement, JSW Foundation launched the ‘Beyond Broom’ project across six gram panchayats and one town municipality council.

Before the inception of the initiative, the region faced significant waste management hurdles, particularly in the disposal of wet waste, which was predominantly directed to landfills due to space constraints for composting. Dry waste processing was the only viable option. Recognising this challenge, the project aimed to revolutionise waste management practices by decentralising composting and promoting resource recovery.

The project's multifaceted approach included securing land for composting, advocating for space allocation from panchayat members, and conducting information, education, and communication (IEC) programmes to raise awareness about proper waste management practices. Additionally, the initiative focused on capacity building through training, implementing door-to-door waste collection services, ensuring scientific waste disposal, and engaging diverse stakeholders - including community members, ASHA workers, anganwadi teachers, village water and sanitation committees, schools, farmers, and local scrap dealers.

In the reporting year, 16,015 households were covered and 1,735 tonnes of waste was collected. Beyond the quantitative metrics, the initiative has contributed to creating a cleaner and greener environment while empowering communities in waste management endeavours.

The Beyond Broom project stands as a testament to the transformative potential of community-driven initiatives in waste management. By fostering collaboration, raising awareness, and implementing sustainable practices, the project has not only addressed waste management challenges but also empowered communities to take ownership in environmental stewardship.

We are deeply committed to transparency and sustainable products, prioritising consumer safety above all else. Our dedication extends beyond mere environmental considerations to actively protecting the environment, conserving resources, and surpassing regulatory standards. Our ultimate aim is to ensure the well-being of our customers and end-users, with customer satisfaction serving as the ultimate metric of our success

Our relentless pursuit of value for our customers is evident across all our businesses within the JSW Group. We strive to be the preferred supplier in all markets while enhancing societal well-being.

We have achieved notable milestones, receiving the GreenPro certification for our JSW Neosteel TMT bars, and 14 categories of Roofing Sheets, and becoming the first manufacturer to earn the prestigious GreenPro ecolabel for our Automotive Steel products. This recognition reflects our leadership and steadfast commitment to sustainable practices, exemplified by our active involvement in shaping the GreenPro Automotive Steel standards.

The GreenPro ecolabel, developed by the Confederation of Indian Industry's (CII) Green Business Centre, represents the pinnacle of environmental sustainability and product performance in the Indian manufacturing sector. It signifies our meticulous attention to environmental impact throughout our products' lifecycle, from raw material sourcing to end-of-life management. The availability of the GreenPro ecolabel for our Automotive Steel products empowers automotive manufacturers to prioritise sustainability in their supply chains.

Additionally, we have obtained Environmental Product Declarations (EPDs) for all 14 finished products from three of our integrated steel plants and five finished products from three downstream plants. EPDs enable us to transparently communicate environmental information to customers, offering reliable and standardised insights into our products' lifecycle. We firmly believe that sustainable practices are not only essential for value creation but also offer significant long-term benefits for all stakeholders.

![]() Read more about

our Sustainable Products on our website

Read more about

our Sustainable Products on our website