1997

Commissioned 1.6 million tonne Hot Strip Mill for hot-rolled cast products.

JSW Steel, since inception, has been at the forefront of change that has shaped the steel industry. From turning a barren land in Vijayangar into one of the world’s largest steel complexes to contributing to the nation’s iconic infrastructure projects, we have set industry benchmarks while producing world-class steel that fosters progress and prosperity. We are now pioneering green steelmaking, aligned with India’s sustainable development aspirations and the global agenda for a low-carbon future.

On the way, we are transforming as a company, setting JSW Steel on a long-term, profitable growth path. We are augmenting scale and capacities, deploying emerging technologies, driving innovation, democratising digitalisation and putting sustainability at the core while committing to Zero Harm to the environment, people and community.

Our well-defined pathway to achieve Net Neutral in carbon emissions for all operations under our direct control by 2050 puts us ahead of India’s commitment to the world to become net zero in carbon emissions by 2070, while our focused social interventions are making a difference to more than a million lives.

At JSW Steel, we are not just building the future with steel; we are steering it with strength, resilience, and integrity.

What started as a greenfield project on a barren land in Vijayanagar has evolved into India’s largest single-location integrated steel plant, celebrating world-class steelmaking in India for 25 years. With a production capacity of 12.5 MTPA and an expansive green cover of 18 lakh trees spread across 7,800 acres, the journey of the Vijayangar plant reflects our commitment to building a sustainable future, driven by technology adoption, innovation and excellence, as well as environmental and community well-being. We aspire to make it the world’s largest steel manufacturing complex, with the potential to expand capacity to 25 MTPA over the years.

A hub of innovation and heritage

The Vijayanagar Experience Centre is more than a mere display of industrial strength; it represents the melding of art, culture, and sustainability. The centre provides an immersive view of the plant’s operations, showcasing innovations in steel production and environmental stewardship.

Art, sports, and community development

Vijayanagar fosters a vibrant community where dreams are nurtured and talent flourishes. The Inspire Institute of Sport (IIS) stands as a prime example, developing athletes who have brought pride to the nation on the international stage. Further, the rich cultural heritage of the region is celebrated, particularly with initiatives like the construction of Kaladham - the heritage precinct within our township - and the restoration and preservation of heritage sites of Hampi.

We believe steel is at the heart of economic progress and prosperity, with its versatility and infinite recyclability. From high-speed rail networks to highways and bridges, from nuclear power plants to renewable energy projects and oil and gas pipelines, the world-class steel we make goes into building India’s critical and large-scale infrastructure projects that form the backbone of the nation’s aspirations to become a developed economy over the next two decades. We are also enabling our customers to manufacture products that are safer, efficient and sustainable.

JSW Steel also contributes significantly to India's energy sector, providing materials for solar and wind energy projects. Our high-performance steel products are integral to constructing robust and efficient energy facilities that aid the nation's shift to sustainable energy sources.

Our specialty steel products are critical in constructing extensive water and oil & gas pipelines. These high-durability materials ensure the integrity and longevity of pipelines, which are crucial for the nation's resource distribution networks.

To support India's growing infrastructure needs, JSW Steel supplies high-strength steel for the construction of highways and bridges. Our materials enhance the durability and safety of these essential transportation links, facilitating economic growth and connectivity across regions.

JSW Steel also contributes significantly to India's energy sector, providing materials for solar and wind energy projects. Our high-performance steel products are integral to constructing robust and efficient energy facilities that aid the nation's shift to sustainable energy sources..

Our specialty steel products are critical in constructing extensive water and oil & gas pipelines. These high-durability materials ensure the integrity and longevity of pipelines, which are crucial for the nation's resource distribution networks.

To support India's growing infrastructure needs, JSW Steel supplies highstrength steel for the construction of highways and bridges. Our materials enhance the durability and safety of these essential transportation links, facilitating economic growth and connectivity across regions.

At JSW Steel, we are on evolving as a company, with a focus on end-to-end digital transformation across our operations – from mining to logistics. As we stand on the cusp of multidecadal opportunities, we are leveraging the power of digitalisation and data analytics to improve decision-making, increase productivity, enhance operational efficiency, strengthen systems and processes, and make the workplace safer. We are also building a future-ready workforce while upholding the highest standards of transparency and integrity in engaging with our customers and other stakeholders.

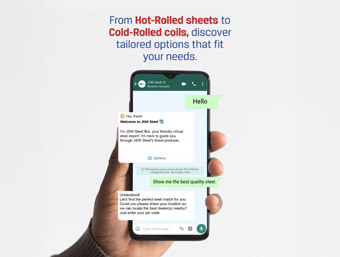

Our ‘Digital Engagement’ project utilises omni-channel capabilities and AI-driven automation to refine lead management and personalise customer interactions. This includes the integration of AI chatbots and automated lead enrichment processes, enhancing customer satisfaction and sales efficiency.

The ‘Pit to Plant’ logistics management system, featuring RFID-based vehicle authorisation and automated weighbridge operations, has reduced truck turnaround times by 51%. This increase in efficiency ensures the timely delivery of raw materials to the plant, optimising our mining operations.

Embracing Industry 4.0 principles, we focus on predictive maintenance and process optimisation using AI and ML algorithms. These technologies help predict gas channelling in blast furnaces and optimise combustion efficiency, thereby reducing coke costs, minimising downtime and boosting operational efficiency.

The AIKYAM One View App, a unified platform for customer engagement, consolidates customer interactions, offers real-time order tracking, and provides access to financial information. The in-app AIKYAM bot further enhances customer support, significantly improving overall customer experience and satisfaction.

The Integrated Control Tower (ICT) for real-time performance monitoring acts as a single source of truth for data across the organisation, enhancing transparency and decision-making. Additionally, advanced analytics models improve efficiency in the pellet plant and steelmaking processes.

Our APS system integrates demand forecasting, inventory optimisation, and real-time data analytics to enhance forecast accuracy, reduce planning time, and improve capacity utilisation. This system has strengthened supply chain efficiency and customer satisfaction by ensuring better order fulfilment and effective inventory management.

The SAMPARK project digitises road outbound processes - including automated vehicle and driver verification, real-time tracking, and milestone-based vehicle management. Integration with platforms like Freight Tiger for vehicle tracking and mParivahan for verification, has streamlined logistics operations, reduced costs and improved on-time delivery performance.

Steel plays a crucial role in nation-building, but also contributes significantly to industrial CO2 emissions, accounting for 12% of India’s total energy infrastructure CO2 emissions. As India progresses rapidly on its development path, JSW Steel is committed to pioneering clean and green steel production. We have established a clear roadmap to become net neutral in carbon emissions for all operations under our direct control by 2050, much ahead of India’s commitment to the world by 2070.

In our pursuit of reduced carbon emissions, we plan to invest US$1

billion across our

operations. We became the first steel company globally

to raise

US$500 million through

US dollar-denominated Sustainability Linked Bonds.

IN CENTRE STAGE

Project SEED (Sustainable Energy Environment and Decarbonisation), our flagship decarbonisation initiative, initially launched at Vijayanagar and extended to Dolvi this year, is at the forefront of our efforts.

Project SEED was recognised as one of the top Global Energy Transition Changemakers at COP 28

Our decarbonisation strategy is structured around ambitious long-term targets, announced by the International Energy Agency’s (IEA) Iron and Steel Technology Roadmap (2020). This roadmap supports the Paris Agreement's objectives to limit global temperature rise to below 2°C, ideally to 1.5°C. For India's iron and steel sector, this translates to a reduction in direct emission intensity by over 60% by 2050, with JSW Steel setting a trajectory to achieve a derived emissions intensity of zero by 2050, encompassing both direct (Scope 1) and indirect (Scope 2) emissions.