We strive to provide a healthy and safe environment for our employees, contractors, business associates, visitors and communities. It starts with complying with all applicable health and safety regulations. We have implemented best-in-class Occupational Health and Safety (OHS) management systems, which are continuously benchmarked against global best practices, to achieve our vision of ‘Zero Harm’.

Highlights FY 2021-22

LTIFR - 0.28 Target for

FY 2022-23

Safety Observations

Corrective and Preventive actions (CAPA) implemented

e-learning modules on safety completed

Planned safety

Inspections & Internal

Audits undertaken

LTIFR for employees

LTIFR for contractors

LTI

During the year, we regret to report eight fatalities consisting of one employee and seven contractors.

* Vijayanagar, Dolvi and Salem works

Awards & Recognitions

01

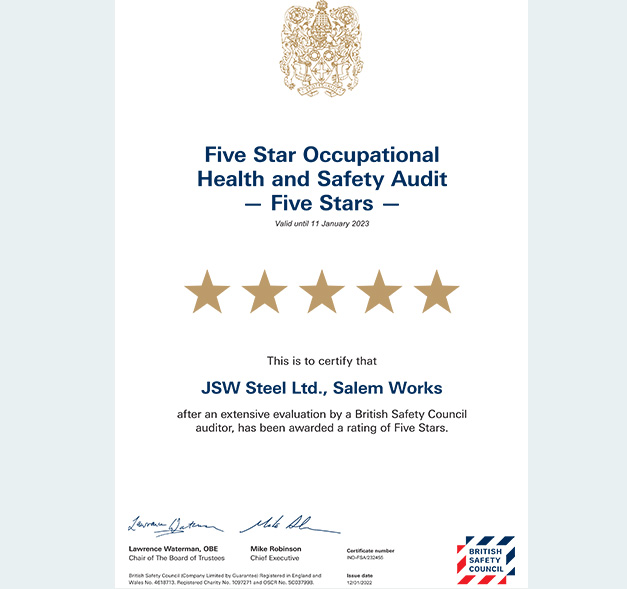

JSW Steel Salem became the first integrated steel plant (ISP) globally to be recognised with 5-star Occupational Health & Safety from British Safety Council against 2021 specifications.

02

JSW Steel Dolvi won the Platinum Health and Safety award 2021, from the Indian Chamber of Commerce (ICC), Kolkata in the Metal and Mining Sector.

03

JSW Steel Salem received the Award of Honour from the National Safety Council, Tamil Nadu Chapter for excellence in Occupational Health, Safety and Environment 2020.

04

JSW Steel Dolvi won the International Safety award 2022 award with Distinction from British Safety Council.

Key initiatives undertaken during FY 2021-22

01

Health & Safety Strategy was reviewed and the key focus areas identified are Leadership & Culture, Risk Management & Control, Capability Building, Contractor Safety Management and Assurance & Audit

02

Digitised safety management information system across all the sites

03

Digital interventions to reduce manmachine interface

04

Theme-based monthly safety campaign at all the locations

05

Skill assessment and development programme launched at all the sites

06

NEBOSH International General Certification for safety professionals

07

‘Safety Hero Program’ to recognise employees and contract workers who bring about positive change in the safety culture

08

Performance indicators KRAs up to 15% are linked to employee’s variable pay

Leadership and culture

Safety Observations

Safety observation involves structured, planned and proactive safety conversations with the workforce in their workplaces to achieve positive behavioural change. We implemented Safety Observation (SO) programme to institutionalise felt leadership, which gained traction with site leadership teams.

Employees undertook the Safety Perception

Survey launched at the Salem plant

To further strengthen Health & Safety at the workplace, the ‘Safety Dragnet’ programme was launched at the Salem site. Safety Dragnet has representations from the top management, zonal heads and department heads along with 41 employees who were nominated as a DSEO (Department Safety & Environment Officer) and 235 associate employees who were nominated as ASC (Associate Safety Champion). Nominated DESOs and ASCs have the core knowledge of operations mechanical and electrical safety functioning, and together they promote a safe working environment by coordinating line walk safety inspections, cross-functional team safety audits, ensuring compliance to safety-related action points to bring positive change in the safety culture.

Safety Perception Survey

Safety Perception Survey was launched at the Salem plant with 5,100 employees, associates and contract workmen to understand behavioural, cultural and personal perspectives about safety. The assessment consisted of an online survey, one-on-one interviews and focus group discussions providing insights into challenges and opportunities that are required for the next steps and interventions.

Line Management Ownership

Several initiatives were undertaken by site leadership teams to enhance line management ownership and capabilities. These initiatives included participation in safety observations, incident investigations, line manager walkthrough, Gemba walk, emergency drills, safety training, road safety inspections, safety marches, participation in divisional improvement committees, sub-committees and Apex meetings.

Group standards, audit and assurance

Group standards, Group recommended practices and guidance notes

During FY 2021-22, we rolled out 13 group recommended practices focused on contractor safety management, construction safety, and risk management standards. We also established ten construction-specific ‘guidance notes’ for improving safety.

JSW critical safety rules

We launched 10 JSW critical safety rules based on the criticality and history of past incidents. A 3D animated video was developed and cascaded to all the sites to be included in the safety induction process, creating awareness around these rules.

External audits

Our Salem plant achieved 5-star rating for Occupational Health & Safety from the British Safety Council. Moreover, external baseline safety audits were conducted at the newly acquired BPSL Kolkata, Chandigarh and JSW Anjar sites.

Risk Management and Control

Risk assessment

Fire Safety Risk Assessments were carried out at six coated products sites to identify fire risks potential and improve our fire safety management.

Process safety management

Our Dolvi plant continued to engage with DSS+ for developing the Centre of Excellence in Process Safety Management (PSM).

Hazard Operability studies were conducted at BPSL Kolkata and Salem Works.

Contractor safety management

CSM process

We established a six-step Contractor Safety Management (CSM) programme and CSM sub-committees at all plants.

CARES (Contractor Assessment and Review for Excellence in Safety)

Over 1,600 contractors across our businesses have been assessed against CARES framework and rated for their safety performance.

Capability building

Safety Champion programme for line managers

The programme will create more than 1,000 Safety Champions who would act as safety ambassadors at their respective plants. Under the programme, 10 safety modules were developed in coordination with the British Safety Council to increase safety awareness of line managers and actively engage them as safety ambassadors.

International training and certification for safety team

Digital

Our digital safety assets include online safety training modules, a safety app and portal. We have digitised all our safety information systems, such as incident reporting, audit and inspection, safety observation, contractor safety management, road safety and monthly safety performance reporting. At Vijayanagar Works, we are using Augmented Reality (AR)/Virtual Realty (VR) enabled emergency response training to our employees. We launched new e-learning programmes focusing on office safety, fire safety, process safety, constructions safety, wellbeing, display screen equipment and defensive driving.

New e-learning modules launched

during FY 2021-22

H&S priorities FY 2022-23

01

Process Safety Management - Centre of Excellence at VJNR

02

Capability building and skill development

03

Safety Experience Centre

04

Digital initiatives

05

Felt leadership programme

06

Group safety audits

Case Study

AR/VR-enabled emergency response training

Fire is a major hazard in a built environment. Live firefighting training requires significant resources and open spaces, apart from having an adverse environmental impact. It is also not possible to simulate different kinds of emergency scenarios. To overcome these challenges, we have implemented an AR/VR-enabled emergency response training.

VR firefighting trainer removes the need to imagine a difficult situation and instead replaces it with a realistic simulation. The desired outcome was achieved at low cost, with no injury, no additional space and zero emissions. It provides an effective learning experience so that the trainees can respond in real time and with authentic spatial understanding to the danger at hand. It combines high fidelity virtual fire environments with real-time physical interfaces to deliver the real virtual training experience, any place, any time in a safe, cost-effective manner. This prepares firefighters and Rakshaks for the risks associated with fighting fires.