EFFICIENT CAPITAL ALLOCATION

- Economic performance

- Climate change and emissions management

- Vendor management and development

- Energy use and management

- Water resource use and management

- Investment in clean technology and environmentally friendly products

Domestic crude steel capacity

(including 1.7 MTPA under

commissioning)

Targeted domestic crude steel

capacity by FY 2030-31

Capex programme

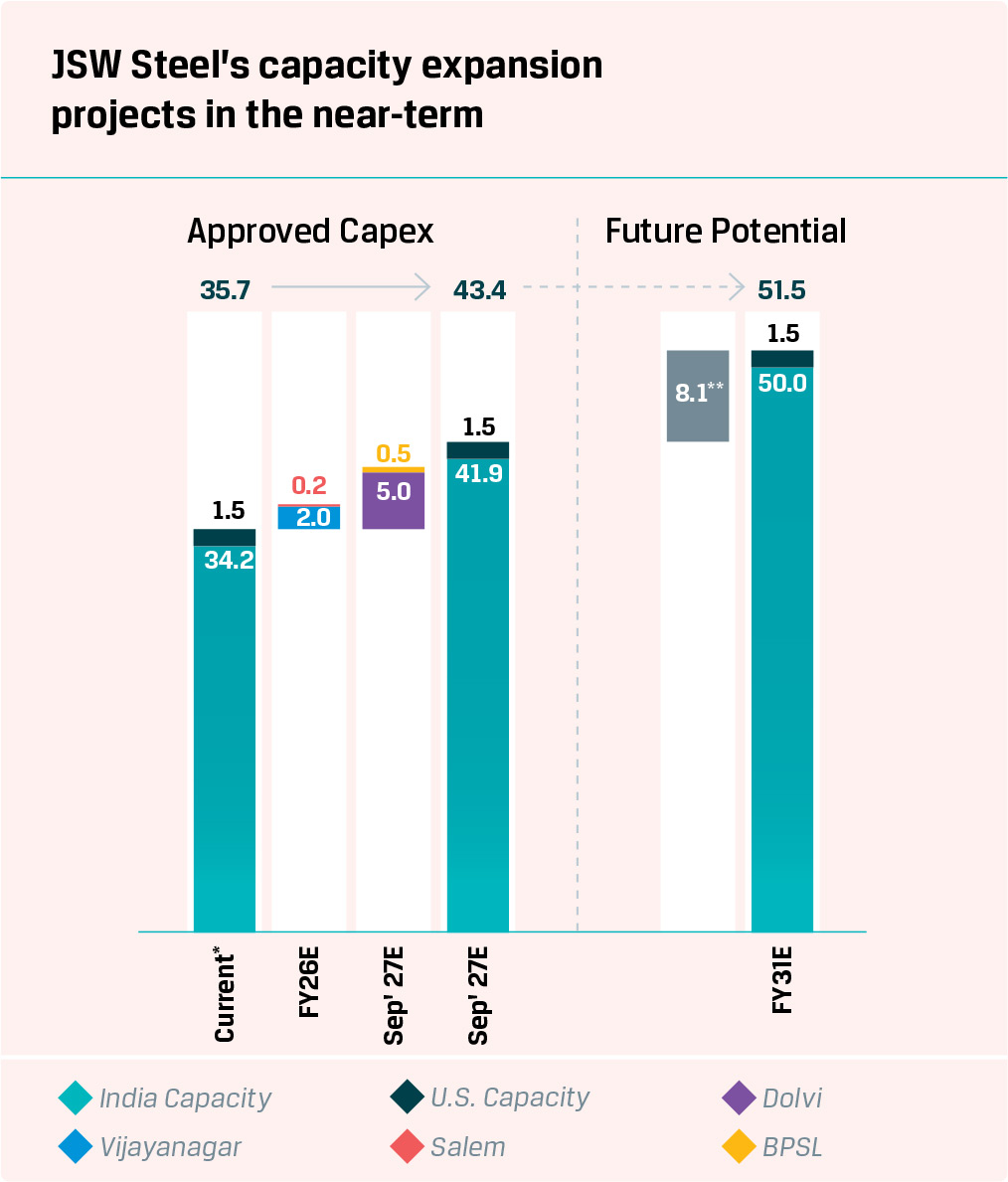

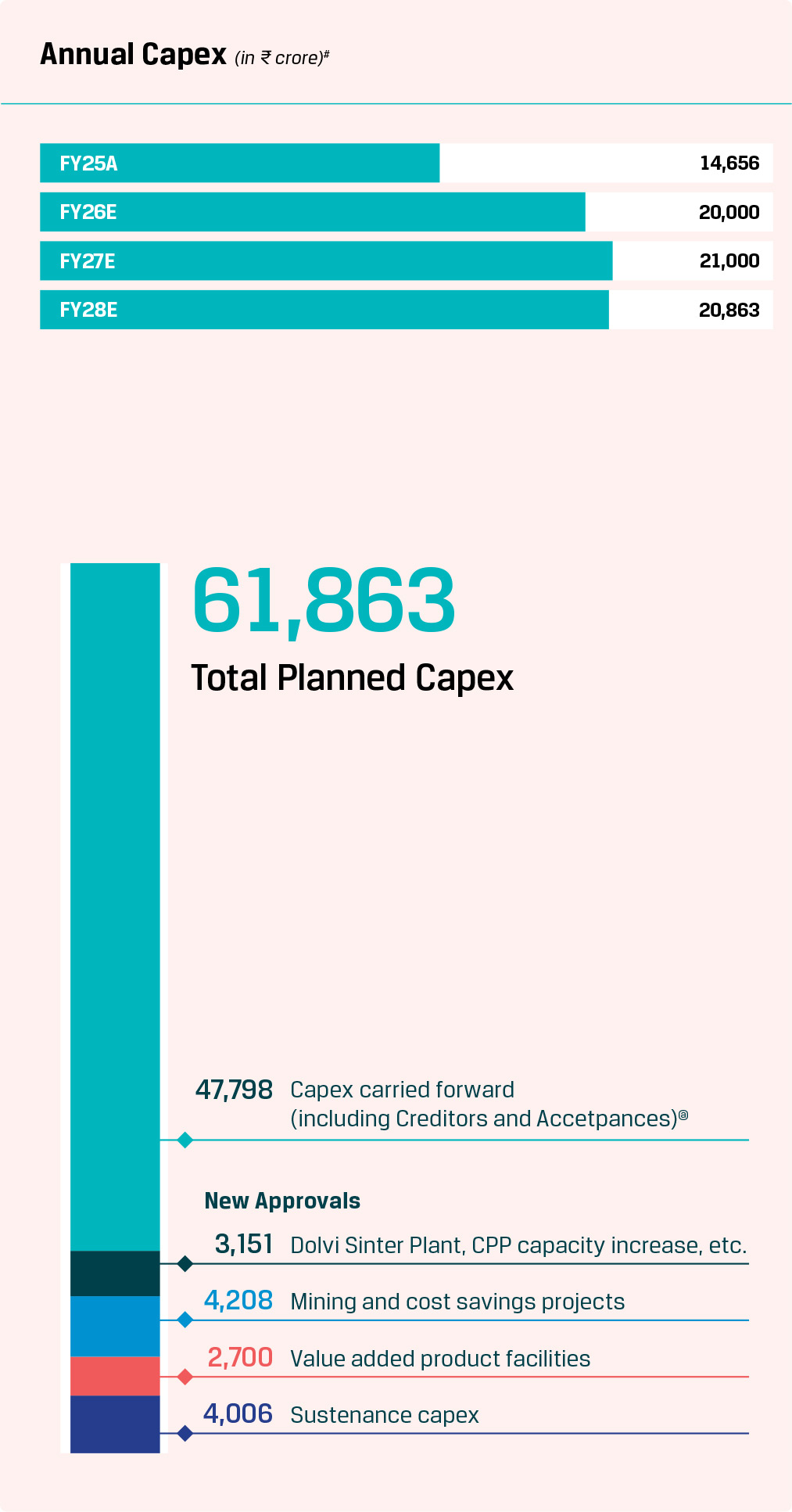

Our capital expenditure strategy aims to ensure long-term growth, operational excellence and market leadership. With a planned investment of ₹61,863 crore, we are progressing confidently across multiple fronts. Key expansions are progressing well, with Vijayanagar ramping up steadily, Dolvi and Odisha projects advancing as planned, and the colour-coated line in Jammu & Kashmir successfully commissioned, achieving several key milestones. FY 2024-25 witnessed a capex of ₹14,656 crore, with capex expenditure rising to ₹20,000 crore in FY 2025-26. From capacity augmentation and raw material efficiency to enhanced product value and regional accessibility, each initiative aligns with our ambition to strengthen capabilities and ensure a future-ready business.

* 1.7 MnT capacity at Vijayanagar under commissioning | ** Subject to Board approvals | # Approximately 96% of capex is for India operations and 4% is for overseas operations | @ Reduced by ₹1,980 crore following transfer of Slurry pipeline to JSW Infrastructure in FY 2024-25

Key project updates

Vijayanagar

The 5 MTPA integrated steel making project at JVML, Vijayanagar is nearing completion. During the year, JVML has successfully commissioned a 4.5 MTPA blast furnace which is ramping up well and operated at over 90% capacity utilisation in March 2025. JVML has also commissioned Steel Melt Shop with a capacity of 3.3 MTPA with one converter and both casters fully operational. The second converter at the SMS is expected to be commissioned in Q2 FY 2025-26. The commercial production and sales from the HSM unit commenced in March 2024. The other allied facilities like the Raw Material Handling System, Sinter Plant, Lime Calcination Plant and the material handling facilities have been commissioned.

Elsewhere at Vijayanagar, the Coke Oven project comprising four 0.75 MTPA batteries is advancing well with three batteries commissioned and the final one scheduled for completion by end of FY 2025-26.

BLAST FURNACE 3

We plan to revamp and upgrade the Blast Furnace 3 from 3 MTPA to 4.5 MTPA along with associated auxiliary units. This upgradation will increase the crude steel capacity to 19 MTPA at Vijayanagar and provide cost savings due to larger Blast Furnace operations. The project is expected to be commissioned in Q4 of FY 2025-26.

Dolvi

The Dolvi Phase III expansion aimed at increasing capacity

from 10 MTPA to 15 MTPA, is progressing as planned. The

project includes installations of state-of-the-art facilities

such as 4.8 MTPA Blast Furnace, Steel Melt Shop of

5 MTPA

and Hybrid Continuous Strip Mil that can produce plates and

coils. The project includes setting up of 250 MW captive power

plant which will utilise the excess gas available from the

Blast Furnace reducing the overall power cost at Dolvi.

Key long lead time equipment and materials have already been ordered with Letters of Credit firmly established to ensure seamless procurement and execution. This strategic capacity enhancement will further strengthen our market position. The project is on track for completion by September 2027.

BPSL

At Bhushan Power & Steel Limited, the Phase II expansion from

3.5 MTPA to 4.5 MTPA was completed in Q2 of FY 2024-25.

Additional upgrades in Phase II expansion included capacity

enhancement of BF 1 and BF 2 through PCI grinding, drying

units, and dynamic flow control valves; Lime Calcination Plant 6

for expanded calcined lime supply; a coal drying unit to reduce

moisture in DRI and power plant coal; capacity augmentation in

Raw Material Handling System to enhance unloading efficiency;

commissioning of the Billet Caster and Wire Rod Mill-2.

The project has ramped up well with BPSL achieving a crude steel

production of ~1 MnT in Q4 of FY 2024-25. The commissioning

of the Wire Rod Mill -2 will enhance the product mix portfolio

enabling BPSL to manufacture alloy wire rods and

value-added

special products enhancing EBITDA margins.

Odisha

Significant progress is underway on our 30 MTPA, 302-km slurry pipeline project in Odisha which remains on track for commissioning in FY 2026-27. This critical infrastructure will enhance raw material transportation efficiency and support long-term cost competitiveness. Simultaneously, the construction of our 8 MTPA pellet plant in Odisha is advancing steadily also targeted for commissioning in FY 2026-27.

JSW Steel Coated Products

The 0.12 MTPA Colour Coating Line in Jammu & Kashmir was successfully commissioned in the fourth quarter of FY 2024-25, marking a significant milestone in our value-added product portfolio expansion. Strategically located to cater to the growing demand in the northern region, the facility enhances our manufacturing footprint while offering greater operational efficiency and customer proximity.

Green Steel

In line with our Company’s strategy to set up a Green Steel plant in order to cater to the export requirements, manufacturing steel with low carbon emissions, the requirement to track the CO2 emissions separately and exploring new technology like green hydrogen usage for DRI operations, the Board of Directors approved the transfer of the existing Salav unit having DRI capacity of 0.9 MTPA along with its auxiliary units to JSW Green Steel Limited. We have carved out the Salav unit into JSW Green Steel Limited and plan to set up a green steel facility by expanding capacity to 4 MTPA in phases.

OUTLOOK

Near-term

- Commissioning of the SMS converter 2 at JVML in Q2 of FY 2025-26 and full ramp up to 5 MTPA by Q3 of FY 2025-26.

- Upgradation of Blast Furnace 3 at Vijayanagar to increase capacity to 4.5 MTPA from existing 3 MTPA by Q4 of FY 2025-26.

- Construction of the additional 5 MTPA capacity at Dolvi to increase capacity to 15 MTPA for commissioning by September 2027.

- Establishing a 1 MTPA greenfield Electric Arc Furnace (EAF) plant in Andhra Pradesh to increase production capacity and support green steel initiatives.

- Set up of 4 MTPA Green Steel capacity in two phases at Salav.

- Continued exploration of value-accretive acquisition opportunities in India to enhance our domestic capacity and operational synergies.

Long-term

- Target to reach 50 MTPA capacity in India and consolidated 51.5 MTPA capacity by FY 2030-31.

- Complete the development and commissioning of the upcoming 13.2 MTPA greenfield steel plant in Jagatsinghpur district, Odisha. The plant will play a key role in the growth story of JSW Steel and India.

- Maintain and grow our share of steel production in India, contributing to India’s National Steel Mission.