TO A LOWER CARBON FOOTPRINT

ENVIRONMENT

JSW Steel is guided by a core philosophy—minimising our environmental footprint while fostering ecological well-being. We remain committed to innovating and deploying cutting-edge technologies and adopting transformative practices to drive continual improvements in our processes, products and performance. We also consistently engage with our varied stakeholders to promote environmental awareness and advance conservation efforts aimed at safeguarding our surrounding ecosystems. By undertaking such ambitious actions, we ultimately endeavour to accelerate the uptake of sustainable practices across the steel industry.

Embedding a Just Transition into Our Climate Strategy

As part of our broader commitment to responsible decarbonisation, JSW Steel has adopted a formal Just Transition Policy, recognising that the path to a low-carbon future must be inclusive, equitable, and socially responsible. While our decarbonisation journey aims to reduce emissions and build climate resilience, we also acknowledge the potential socioeconomic impacts it may create—particularly on workers, communities, and supply chains. Our Just Transition framework is designed to ensure that the benefits of the green transition are shared widely, while risks are mitigated with empathy and foresight.

The policy is grounded in core principles of sustainable development, decent work, social inclusion, and respect for human rights. We aim to embed these principles into our enterprise risk management framework, complemented by targeted measures such as stakeholder consultations, worker reskilling initiatives, community engagement efforts, and support for our value chain partners. Particular attention is devoted to the most vulnerable groups—whether it is workers at risk of job displacement, small suppliers navigating transitions, or communities adapting to evolving economic and environmental landscapes.

Our approach includes supporting skill development for Sustainable jobs, investing in local infrastructure, and ensuring access to sustainable livelihoods for affected populations. Through transparent disclosure and inclusive governance, we strive to demonstrate accountability, advocate for fair climate action, and ensure that no one is left behind in the pursuit of our net-zero goals. This reinforces our belief that climate action and social responsibility must go hand in hand for a truly sustainable future.

Read more about JSW Just Transition PolicyDJSI Leadership

We are happy to inform our stakeholders that JSW Steel has been included in the DJSI World Index, as well as the DJSI Index for Emerging Markets, for the second consecutive year. We had participated in the 2024 S&P Global Corporate Sustainability Assessment conducted to construct the Dow Jones Sustainability Indices and received an S&P Global ESG Score of 82, which puts us in the 99th percentile, securing the 2nd position globally in the steel sector.

#2

Rank in the global steel industry as per the S&P Global Corporate Sustainability Assessment 2024

82

S&P Global ESG Score

99th Percentile

Certified for responsibility

In FY 2024-25, we took a major leap in our sustainability journey by earning the prestigious ResponsibleSteel™ Certification for four key manufacturing sites—our Integrated Steel Plants in Vijayanagar, Dolvi, and Salem and the Tarapur Downstream Rolling Mill. This global certification, the first of its kind, recognises steel produced to the highest environmental, social and ethical standards. With over 80% of our primary steel production in India now certified, we are setting new industry benchmarks. Tarapur also stands tall as India’s first certified downstream rolling mill. These achievements reaffirm our role in shaping a more responsible steel future.

>80%

Of our primary steel production in India is now certified

Key certifications

AND PERFORMANCE

Climate Change

Climate Change

Energy

Energy

Resources

Resources

Water resources

Water resources

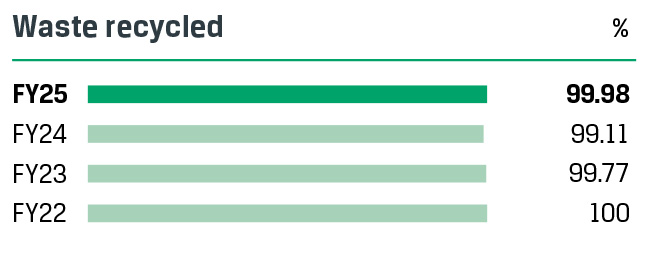

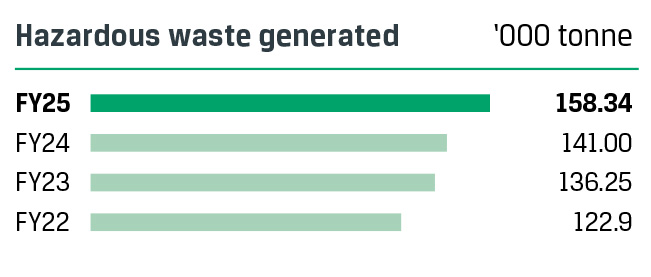

Waste

Waste

Biodiversity

Biodiversity

1.25 lakh saplings planted

>2 million Cumulative saplings planted over the years

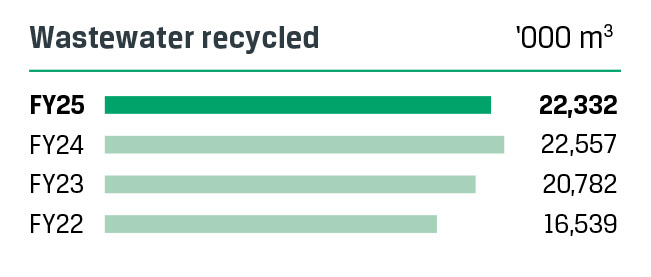

Wastewater

Wastewater

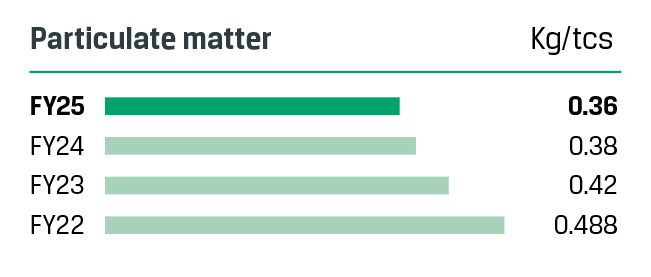

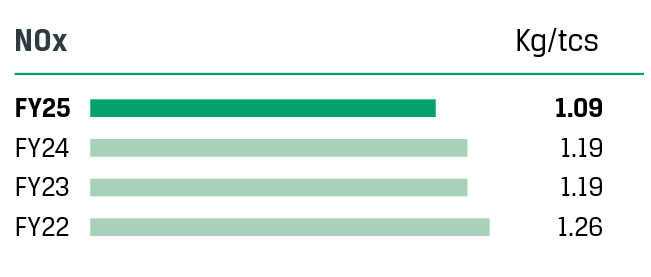

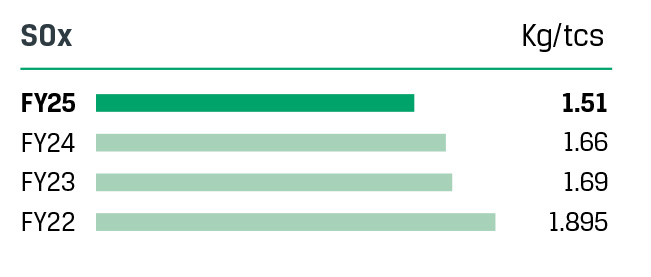

Air emissions

Air emissions

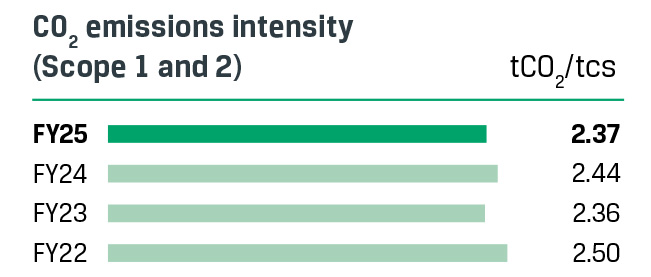

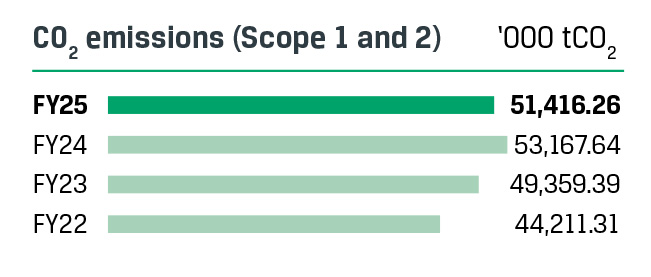

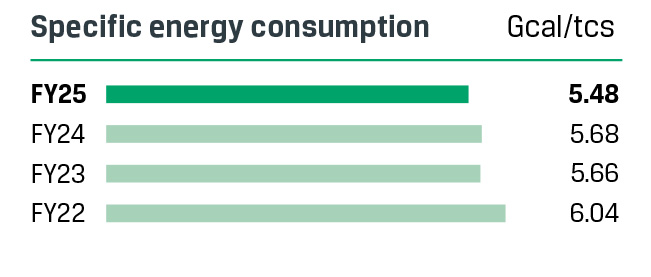

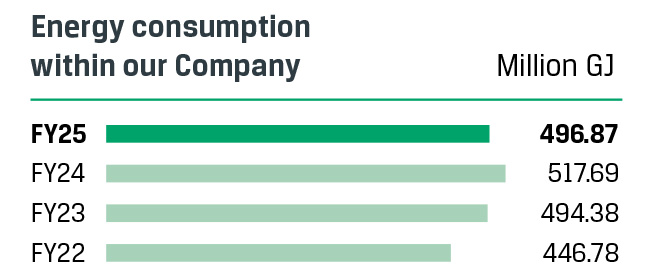

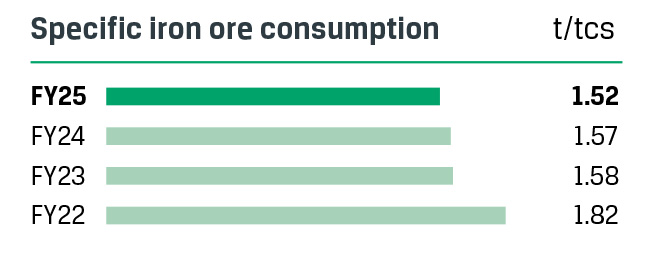

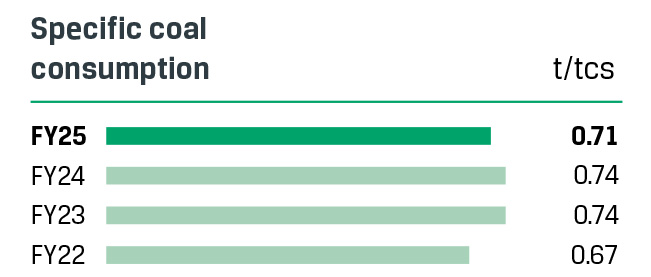

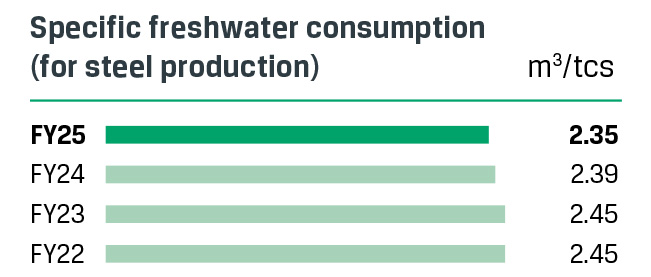

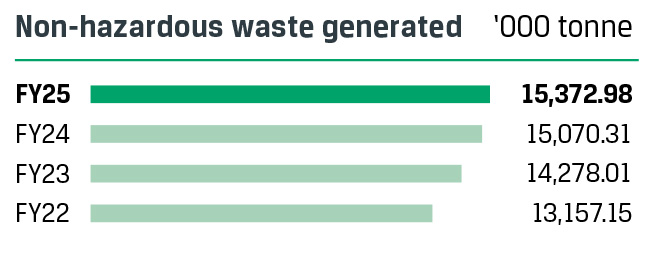

Note: All intensity figures are based on a standalone crude steel production of 21.65 MnT. Progress figures are for integrated operations of JSW Steel standalone ISPs, excluding Raigarh plant. Data for JSW Steel Coated Products are for Vasind, Tarapur, and Kalmeshwar operations.

- Waste data excludes tailings

- Non-hazardous waste diverted from disposal – 15,375.03 ('000 tonne); hazardous waste diverted from disposal – 154.90 ('000 tonne)

- Air emissions data comes from process stacks.