In a world where climate uncertainty is no longer a future risk but a lived experience, we are taking bold steps towards climate resilience. Aspirant to a low-carbon economy, we continue to reshape the way we work and embed sustainability into our purpose, processes and partnerships. By leveraging strategic decarbonisation routes and collaborative innovation, we are not only lowering our carbon footprint but also driving change across the industry, thereby accelerating the transition towards a cleaner and greener future.

Climate governance

Our climate policy is rooted in strong governance and an ecosystem approach. Whether in boardroom debates or in decision-making on the shop floor, climate awareness runs through every layer of our Company. Our climate governance framework functions on four pillars—prevention, adaptation, mitigation and monitoring — ensuring a dynamic and accountable system. We reinforce this framework by aligning it with global standards and frameworks.

Read more about our Climate Change PolicyClimate Action Group

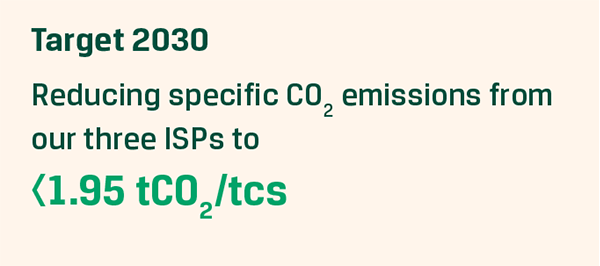

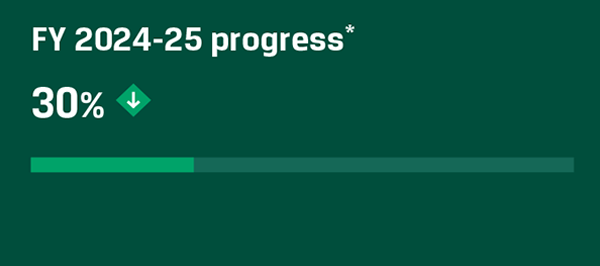

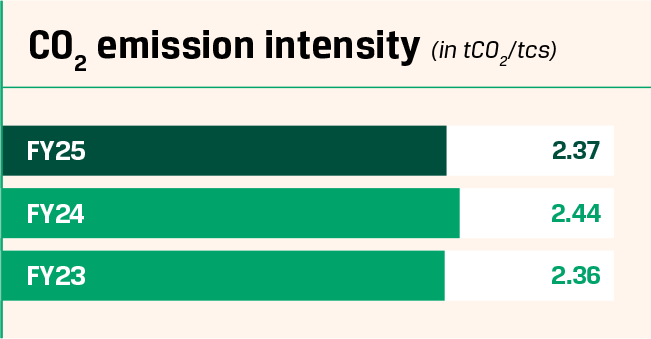

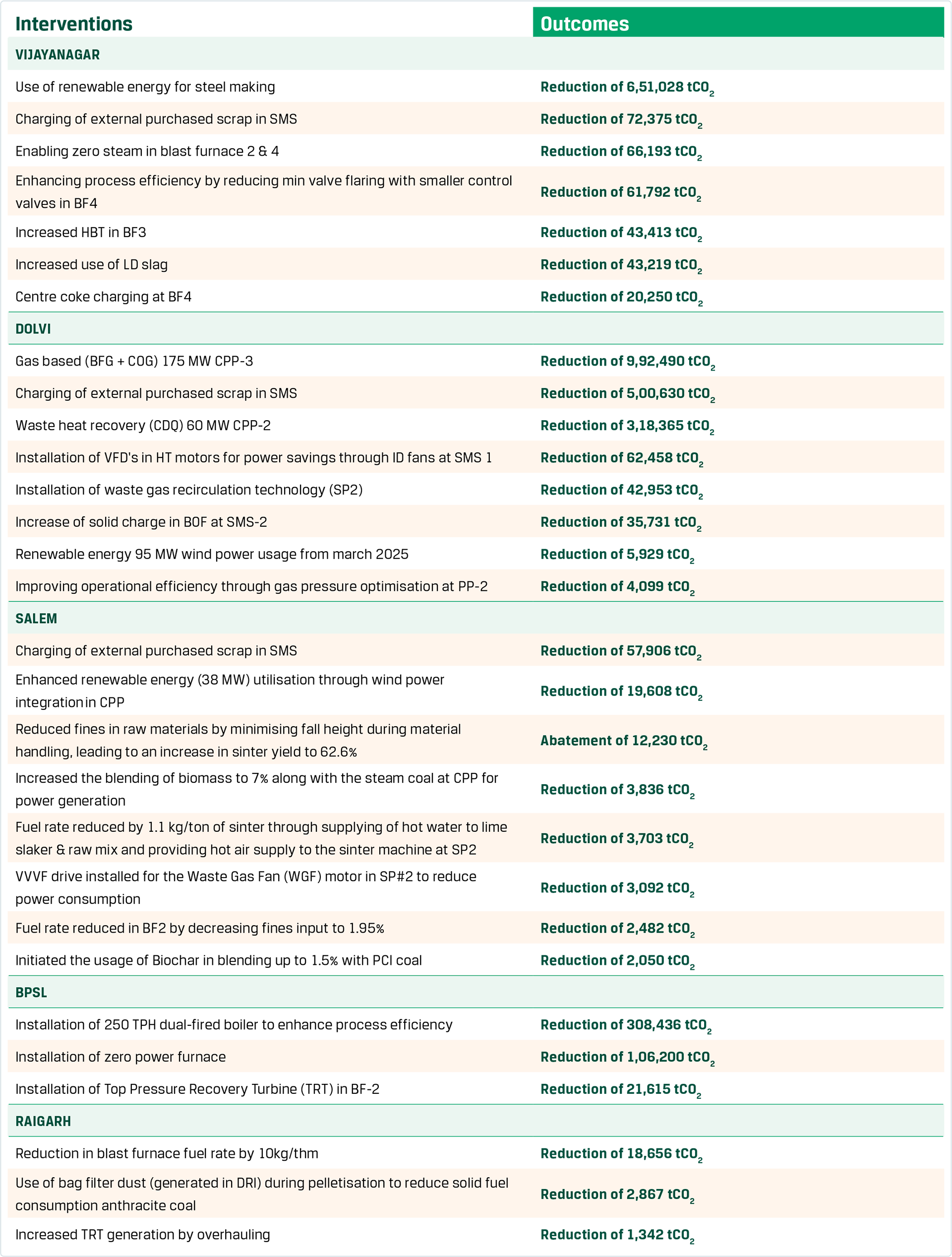

Our Climate Action Group (CAG) has taken on a broader role, overseeing cross-functional activities to pinpoint decarbonisation levers and ingrain climate thinking into everyday business practices. The group uses scenario planning, carbon budget monitoring and opportunity mapping to ensure that our long-term climate goals turn into tangible progress in plants, products and partnerships. The CAG drives our flagship decarbonisation project, Sustainable Energy Environment and Decarbonisation (SEED), to implement changes at the grassroots level. Project SEED targets to reduce 18 MnT of CO2 emissions by 2030 and has successfully reduced 1.87 MnT of CO2 in FY 2024-25 alone, taking the cumulative reduction till date to 3.5 MnT of CO2.

Climate Action Report

We published our first Climate Action Report, available here, which reflects our transparency, accountability and climate commitments. The report outlines our strategy and initiatives to combat climate change. It outlines our approach to managing climate-related risks and opportunities and details the strategic levers, policy measures, and climate resilience initiatives we are implementing to decarbonise our operations.

* Base year considered for reporting the progress across all the parameters is 2005 in line with India’s NDC.

SEED and the COE:

Embedding sustainability at the core of our business and value creation

Executed by SEED and the COE in FY 2024-25

At JSW Steel, we recognise that we live in an era where sustainability is not just a responsibility but a strategic business imperative. In line with this understanding, over the past year, we intensified our efforts aimed at embedding sustainability into the core of our value creation strategy. JSW Steel’s Centre of Excellence (COE), established in FY 2022-23 as a centralised hub of expertise which drives innovation, cost optimisation and sustainable value creation, has emerged as a powerful engine advancing this endeavour.

Amongst the plethora of initiatives under the scope of the COE, SEED (Sustainable Energy Environment Decarbonisation)—our flagship environmental initiative—stands out as a quintessential example of how we are successfully integrating environmental stewardship into our core business operations. SEED aims to deliver measurable reductions in CO2 emissions across our value chain, with an ambitious goal of cutting over 18 million tonnes of CO2 by 2030.

By embedding SEED within the COE's structured, data-driven framework, we have ensured that sustainability is not merely a siloed effort but a centrally governed, enterprise-wide priority at the very nucleus of our business strategy and value proposition. This integration facilitates robust tracking, streamlined implementation, and effective governance—all of which we view as critical hallmarks of a robust and holistic sustainability strategy.

The COE's role in SEED goes beyond oversight. It serves as a catalyst for innovation and leverages cross-functional expertise and digital tools to identify, implement, and scale high-impact environmental projects. In FY 2024–25 alone, the COE executed 565 projects, many of which delivered tangible emissions reductions and helped improve the sustainability and environmental performance of our operations.

By aligning SEED with our broader goals of cost optimisation, digital transformation, and operational excellence, the COE is challenging the notion that sustainability and financial performance are mutually exclusive goals. Instead, it is simultaneously reducing the environmental impact of our operations and enhancing our business' agility, reliability, and longterm competitiveness.

In doing so, JSW Steel's COE and SEED initiative present a compelling business case for other companies navigating the dual challenges of climate change and resource efficiency: when sustainability is strategically embedded into an organisation's DNA, it drives not only compliance but also innovation, resilience, growth, and long-term value creation.

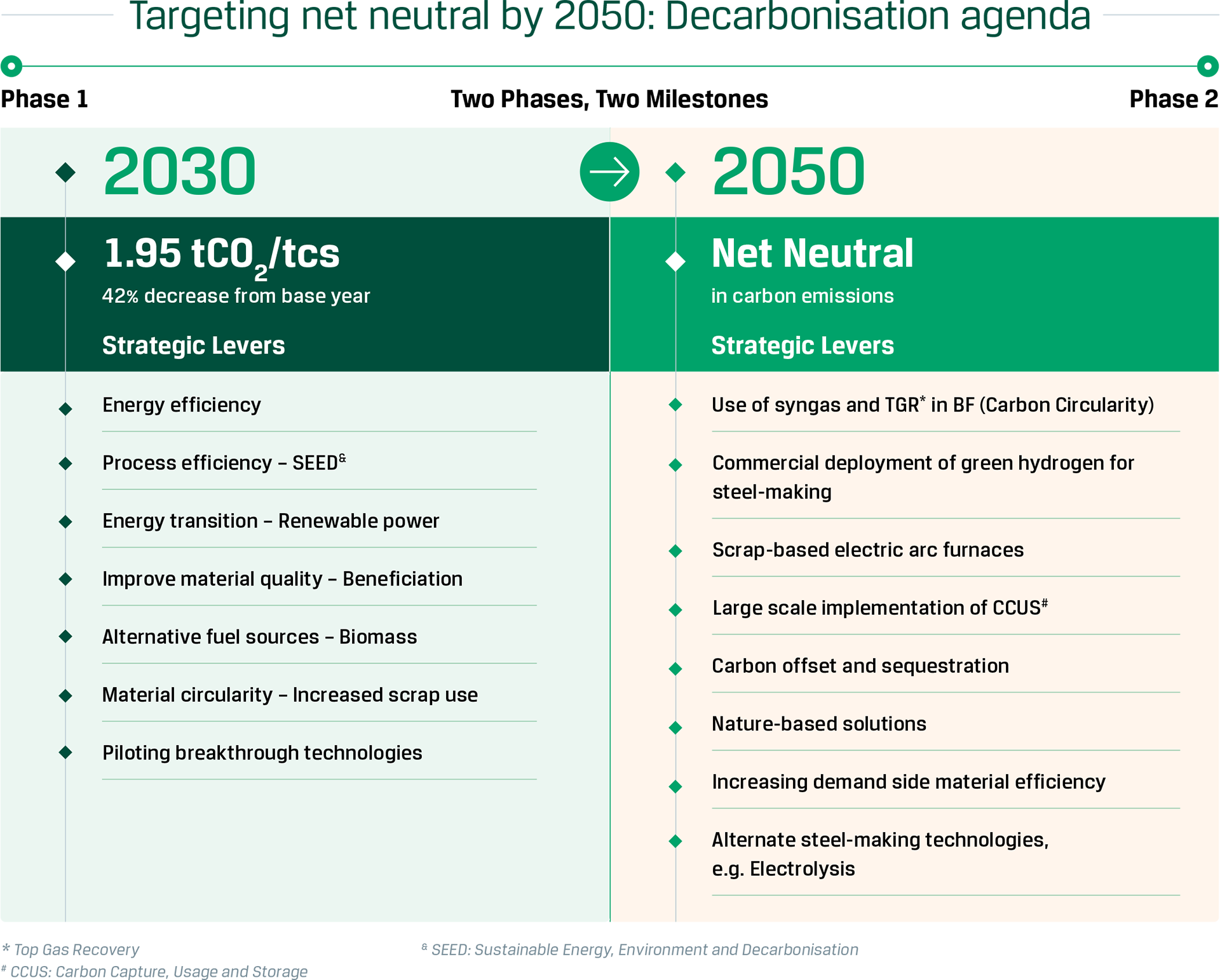

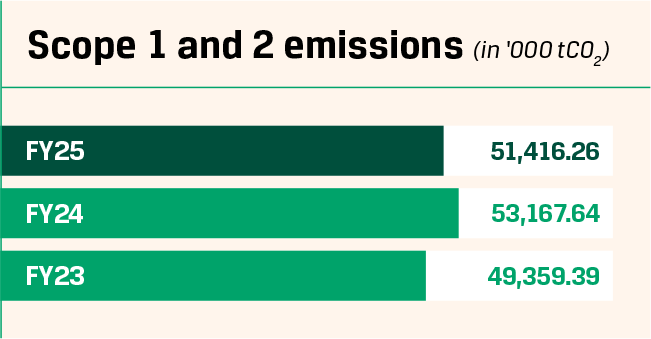

Net Neutral

We are strengthening our mission of attaining net neutrality in carbon emissions for all operations in our direct control. We have expanded the ambit of our emission reduction efforts by catalysing the uptake of cleaner fuels, augmenting the use of low-carbon feedstocks, investing in game-changing technologies and enhancing energy efficiency across our plants.

We continue to make climate mitigation a top priority, aligning our activities with the targets set by global climate accords. To advance our decarbonisation ambitions, we are implementing a varied set of interventions. These include increasing our consumption of renewable energy, promoting circularity in raw material sourcing, expanding the use of alternative and cleaner materials such as biomass and accelerating the development and eventual deployment of hydrogen within our steelmaking processes.

Scope 3 emissions

We are strengthening our knowledge and monitoring of Scope 3 emissions. By charting the entire extent of our value chain from suppliers to end users, we are cultivating a meaningful dialogue with our partners to minimise our collective climate footprint.

During FY 2024-25, we had a credit due to avoided emissions of 5.5 million tCO2 in the categories of ‘Use of Sold Products' and 'Processing of Sold Products', as per the guidance of worldsteel.

We are monitoring our Scope 3 emissions across all 15 categories specified by the GHG Protocol. The applicable categories, as noted below, collectively contributed to net Scope 3 emissions of 8.3 million tonnes of CO2 during FY 2024-25.

- Purchased goods and services

- Fuel and energy related activities

- Upstream transportation and distribution

- Processing of sold products

- Business travel

- Employee commute

- Downstream transportation and distribution

- Use of sold products

The Scope 3 emissions for all applicable categories were calculated in accordance with the technical guidance for calculating Scope 3 emissions issued by worldsteel and the GHG protocol.

Ozone Depleting Substances (ODS)

Ozone Depleting Substances (ODS) are primarily used in cooling systems at our steel manufacturing units. In FY 2024-25, the total ODS consumed at our facilities amounted to 78.66 kgs of CFC-11 equivalent.

Collaborations

We firmly believe that addressing a problem of the magnitude of climate change requires a concerted effort and collaboration from businesses, governments, and civil society organisations. Therefore, we are an active member of several leading global coalitions, sustainability forums, and industry associations that drive progress on climate action, green hydrogen technology, biodiversity preservation, and the acceleration of the energy transition. Our partnerships span across a wide spectrum of expert institutions and enable us to remain at the forefront of climate innovation, be it in alternative fuel uptake or low-emission product development. Together, we are developing innovative solutions for a carbon-constrained world.

We are actively engaged in a range of key initiatives and alliances, underscoring our commitment to forging sustainability through collaboration. These include prominent global platforms such as the International Renewable Energy Agency (IRENA), worldsteel Science Based Targets initiative (SBTi), United Nations Global Compact (UNGC), Responsible Steel (RS), and the World Business Council for Sustainable Development (WBCSD). We also contribute to critical reporting and action frameworks, including Climate Action Charter, Global Reporting Initiative (GRI), and the Climate Group. Domestically, we are part of the India Hydrogen Alliance (IH2A) and the Indian Business Biodiversity Initiative (IBBI).

Our commitment extends to groundbreaking collaborations. We have signed an MOU with the University of New South Wales to test Polymer Injection Technology in our Electric Arc Furnaces. As founding members of EV100+, an initiative dedicated to phasing out heavily-polluting vehicles, we are also actively advancing sustainability across industries. Furthermore, we collaborate with various partners to drive energy efficiency and explore innovative climate technologies. For instance, this year, we entered into a joint study agreement with BHP and Carbon Clean to explore the large-scale deployment of Carbon Clean’s CycloneCC technology, which captures CO2 emissions from steelmaking.

Climate-Related Risks and Opportunities

As climate change intensifies and global regulatory frameworks evolve, we recognise both the emerging risks and the strategic opportunities associated with the transition to a low-carbon economy. In our Climate Action Report, we have outlined our climate strategy along with an assessment of related risks and opportunities. This proactive response stems from our commitment to future-proofing our business, ensuring policy compliance, and bolstering operational resilience, and it is supported by our investments in green technologies, renewable energy, and circular economy initiatives. It further positions us to reduce our environmental footprint, build stakeholder trust and remain competitive in a decarbonising global market.

Carbon Border Adjustment Mechanism (CBAM)

The European Union’s Carbon Border Adjustment Mechanism (CBAM) represents a significant regulatory shift for carbon-intensive sectors exporting to the EU. While the definitive CBAM regime is scheduled to begin from January 1, 2026, the recently published EU Omnibus Proposal introduces a special provision allowing importers to delay the purchase of CBAM certificates until 2027 for goods imported in 2026. The EU plans to release a series of updates, including specific benchmarks, before the end of 2025. However, the long-term implications remain, necessitating a proactive response through enhanced data management, decarbonisation efforts and product carbon footprint assessments.

Carbon Pricing and India’s Carbon Credit Trading Scheme (CCTS)

With the increasing global focus on assigning a cost to carbon emissions, carbon pricing mechanisms are becoming essential regulatory and financial tools in climate policy. India has introduced the Carbon Credit Trading Scheme (CCTS) as a key component of its developing domestic carbon market. Once implemented, the CCTS will impose sector-specific obligations while providing opportunities for emissions trading. In its initial phase, the scheme will apply to energy-intensive sectors such as power, cement, iron and steel, fertiliser, petrochemicals, and oil refineries, all of which contribute significantly to greenhouse gas emissions. We are currently awaiting our specific targets and will assess the impacts accordingly. It is anticipated that the CCTS will help mitigate a portion of the liabilities arising from the EU’s Carbon Border Adjustment Mechanism (CBAM).

Water-Related Risks and Stewardship

Changing rainfall patterns, increasing water stress and competition for shared water resources pose material risks to operations, especially at water-intensive sites. Recognising this, we have deployed a Water Stewardship Program across all our operations. The program focuses on water efficiency, rainwater harvesting, recycling, zero-liquid discharge (ZLD) and community watershed initiatives. These efforts enhance operational resilience, reduce natural capital dependencies on freshwater sources and position us as a responsible water steward in high-stress geographies.

Biomass reduces coal dependency in captive thermal plants

At Salem Works, we have furthered our sustainable energy ambitions by integrating biomass into our captive thermal power plant, which was traditionally fuelled by coal. This initiative blends locally sourced agro-waste such as coffee husks, veneer chips, cattle dung logs and corn biochar into our fuel mix, reducing both our coal dependency and environmental footprint. Guided by a comprehensive feasibility study, we selected biomass with calorific values ranging from 2,200 kcal/kg to 3,800 kcal/kg. Our approach prioritised boiler efficiency, fuel handling and material compatibility, enabling seamless integration.

4,768 MT

Coal replaced with biomass

7.58%

Average blending rate achieved

12,230 MT

CO2 avoided

Advancing sustainability through fuel switching

In FY 2022-23, our Rajpura plant relied on petcoke as the primary energy source for its steam generation boiler, consuming 4,614 metric tons (MT) of petcoke to produce 55,368 MT of steam. However, by dint of its deleterious impacts on both the environment and human health, the government recently instituted regulations prohibiting the use of petcoke across multiple industries. In response, we promptly began transitioning to Piped Natural Gas (PNG)—a cleaner alternative to petcoke—as the primary fuel for our steam boilers.

In FY 2023-24, the plant successfully completed this fuel switch, using 4,278,846 SCM of PNG to generate 57,051 MT of steam. By displacing petcoke, PNG—a cleaner-burning fuel—has resulted in a marked reduction of 5,300 tCO2 per year in CO2 emissions. It has also led to similar declines in particulate matter and ash production, thereby diminishing the overall environmental footprint of the plant’s steam-generation operations. Additionally, this fuel switch has delivered co-benefits for operational efficiency, including more stable boiler performance, reduced maintenance requirements, and a cleaner working environment, thus illustrating how sustainability-driven operational changes are not only supporting our broader environmental goals but also enabling us to realise tangible improvements in process efficiency.

All in all, besides reinforcing our commitment to enhancing the sustainability of our fuel mix and manufacturing processes, this transition serves as a prime example that accentuates how the agility and adaptability of our operations enable us to effectively navigate and comply with a rapidly evolving environmental and climate policy landscape.

5,300 tCO2

Emissions reduction per year

Steam-free steelmaking drive

At Vijayanagar, we have taken a decisive leap in sustainable ironmaking with the rollout of our “Zero Steam” initiative across blast furnaces. Traditionally, steam was injected to facilitate burden softening and manage gas flow, but operational diagnostics showed this practise disrupted the thermal balance, increased coke usage and elevated CO2 emissions. Through advanced thermal profiling, real-time monitoring and fine-tuning of oxygen enrichment, burden distribution and blast parameters, JSW eliminated steam injection in BF-2 and BF-4, saving approximately 8 kg of CO2 per tonne of crude steel. The newly commissioned BF-5 also transitioned to zero steam with similar optimisations. Beyond carbon reduction and cost savings, the initiative has improved furnace stability and control. With plans to embed this model across all furnaces, we are setting a new benchmark in process-led decarbonisation and operational efficiency in steelmaking.

~8 kg

Of CO2 per tonne of crude steel saved